Benefits of a chainsaw

Why is it better to cut logs with a chainsaw into boards rather than using a power tool? There are several reasons:

- You are not tied to electricity, but specifically to an outlet, and can do work in any place convenient for you.

- You can perform work in conditions with high humidity.

- A good chainsaw is much more powerful than an electric one.

- You will be able to work with a chainsaw without interruption for much longer than with a power tool that constantly needs to rest.

Regular cut

If you do not have any available tools, sawing a log with a chainsaw into boards proceeds as follows:

- Sand the log, that is, remove the bark from it.

- Mark the log by drawing the required board dimensions on it.

- Saw the board along these lines.

Please note that with this method you need to separately draw each next board, since quite a lot of wood is lost during sawing - up to one centimeter.

Additional accessories

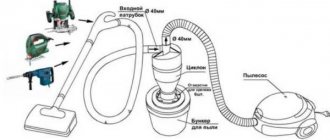

Most often, additional devices are used to cut logs with a chainsaw into boards.

You can either buy such devices or attachments for chainsaws in a store or make them yourself. First, let's look at industrially produced nozzles:

- Debarker. An attachment for a chainsaw, with which you can sand a log, clear it of knots and growths, or cut grooves in a log.

- Nozzles for cross and longitudinal cutting. It is this device for sawing logs with a chainsaw that is used to make boards.

- Petrol cutter attachment. An attachment that allows you to turn your chainsaw into almost a full-fledged grinder. At least for home purposes it is perfect.

In fact, there are a great variety of such attachments, but we will not go into them deeply, since we have already listed those we need for our work above.

How to cut a log lengthwise with a chainsaw - an overview of the most effective devices

All photos from the article

In the process of carrying out various works, there is often a need for longitudinal cutting of logs or timber. For this, a variety of types of equipment can be used - from stationary sawmills to small installations, but these options cost a lot, and if you need to do a small amount of work, then sawing logs with a chainsaw will be the simplest and most rational solution.

In the photo: sawing logs into boards with a chainsaw is carried out using special devices

Advantages of using this option

First of all, let’s figure out what advantages this cutting method has:

| Ability to work in any conditions | Unlike electrical equipment, which is susceptible to high humidity, a chainsaw is capable of working in the most unfavorable conditions, without causing any damage to the structure, because all components in the chainsaw are adapted to work in the open air and even under precipitation |

| Performance | If you are going to work for a long time, then you will need equipment with a power of about 7 horsepower or more, it can withstand significant loads, while the quality of work will be consistently high |

| Autonomy | Since the device runs on gasoline, you do not depend on electricity and can build a structure for sawing in any convenient place. This is especially convenient when working in areas where there are no power lines |

| Convenience | The inertia brake in chainsaws works faster than in electric systems, and smooth starting and adjustable chain speed ensure high quality work, even if you do not have such experience |

Important!

In addition to all the above factors, we should not forget the low cost of the structure; purchasing a stationary sawmill will cost several times more.

Another advantage is the mobility of the device; you can easily transport it to the right place.

Overview of some options

We will tell you about the two most popular designs that provide the best quality when working, and you yourself will determine which is more convenient and preferable in your case.

Homemade option

First, let's look at how to make a device for sawing logs with a chainsaw with your own hands.

The instructions for carrying out the work are as follows:

It is best to use a frame from an old school desk or a square pipe with a side of 20x20 or slightly larger. First of all, two clamps are made, these are elements 50-60 cm long, at one end of which a crossbar with two holes for tightening bolts and a small protrusion in the middle for clamping the tire is welded, an element of the same configuration is attached on top, the photo below shows ready-made elements, as you can see, everything is quite simple, and if you have a welding machine on hand, you can make them very quickly.

The clamps should be sized so that the width of the bolts is slightly greater than the height of the bar

To longitudinally saw a log with a chainsaw, you need a support frame, the width of which should be 7-8 centimeters less than the length, two elements 10 cm long are welded perpendicular to two of the sides, they should be a little larger so that the clamps fit into them, you need install two fixing bolts; for this, a hole is drilled and nuts are welded in order to screw the fasteners into them; a handle is welded in the middle for ease of movement. The system is assembled in the following way: first, the clamps are inserted into the grooves, after which the chainsaw bar is inserted and carefully fixed. The distance is selected depending on the thickness at which sawing needs to be done. To understand how this is done, look at the photo, which shows the assembled structure, the price of the issue is several metal elements and rental of welding for an hour.

This is what the device looks like after assembly

Now we’ll tell you how to cut a log into boards with a chainsaw using this design:

You will need two sawhorses to serve as supports, they should be of such a height as to ensure ease of work. A reliable metal strip or durable board is best suited as a guide. You can make this element from a corner or other metal products. A log is placed below, which needs to be set to the desired height, after which work can begin. After the first pass, the log is raised to the desired height and the process is repeated.

We recommend: Liquid glass for waterproofing – where and how can it be used?

The work is quite simple, the main thing is to set everything accurately and fix it securely

Important!

Do not forget that to operate a chainsaw, a chain for slitting wooden products must be installed; this will ensure high speed and high-quality sawing.

Ready solution

The Big Mill Timberjig option is very popular; it is a special kit for equipping a mini sawmill. Sawing logs into boards with a chainsaw using this device is simple and effective.

By purchasing this option, you get everything you need; we’ll tell you how to organize the cutting of logs:

The design is very well thought out and is simple and reliable.

, the result should be a T-shaped structure. This will be a stubborn ruler. , the delivery set includes corners that are designed specifically for these purposes. . Attach supports to its ends with self-tapping screws; you should not use nails, since they are much more difficult to remove later. , this is done using clamps, which are also included in the kit, remember that the cut line does not go along the edge of the guide, but 10 millimeters higher. , it will be much more convenient to work this way. Fix this position with the help of two supports; if something is not clear to you in the description, look at the photo, everything is shown clearly on it, in addition, the kit always comes with instructions with detailed diagrams.

How to cut a log into planks with a chainsaw? This device allows you to do this easily and quickly

Conclusion

You can cut logs or beams into boards without a sawmill or other massive equipment; an ordinary chainsaw, after a little modernization, can become your best assistant. The video in this article will help you understand this topic even better.

Source: rubankom.com

1

Chainsaw - a universal summer resident tool

A chainsaw, often also called a chainsaw, is a chain-operated hand tool equipped with a two-stroke (in most cases) internal combustion engine. This popular mechanism is indispensable in any homestead. The chainsaw is compact and yet powerful. It works without breakdowns for a long time in autonomous mode, due to which it can be used in any location and in a position convenient for the user. The chainsaw has other advantages:

Equipped with mechanisms for selecting operating speed and smooth starting. Thanks to this, the risk of breaking the circuit is minimized. Can be used in high humidity. Does not require electrical energy. Characterized by high power indicators (significantly greater than those of a power tool). Has a quick-acting inertial brake.

A chainsaw is a chain hand tool

The main advantage of a gasoline saw is the ability to equip it with various attachments. It is they who make it a universal tool, indispensable for the home craftsman. Using a chainsaw, you can saw logs, cut stone, metal, brick, tiled building materials, remove bark from wood, cut out mounting grooves and various recesses in bars.

The functionality of the tool can be expanded even further, the main thing is to choose the right attachment or equip it with a special device.

We will not describe all the capabilities of the chainsaw. In this article, we are only interested in the issue of sawing logs using a chainsaw. More on the features of doing such work with your own hands.

We recommend

Electric saw for aerated concrete Electric nailer for nails Working with a level

Horizontal nozzle

This attachment gives higher accuracy. The device is a rigid frame that is attached to the chainsaw bar on both sides - at the end of the tool and at its base. The device is suitable for logs of small diameter, not exceeding the length of the tire.

Longitudinal sawing of logs with a chainsaw with such a device should only occur after the log is well secured, since if it vibrates during operation, it will not be possible to obtain a flat surface of the board.

Before you start dissolving the log, you need to give it a square shape, cutting off all the excess. It is clear that there will be much more waste compared to industrial production. When cutting a log longitudinally with a chainsaw, the most difficult thing to do is saw off the first board. To do this smoothly, you can use a special frame, which will serve as a guide and serve as a base for the stop. The quality of subsequent boards depends on how smoothly you make the first cut, since the guide will rest on this surface in subsequent cuts.

What will you encounter when cutting logs?

Centuries and millennia pass, new materials and technologies appear, but wood, stone and metal have been and remain the main materials used by humanity for its needs. Products made from them surround us everywhere, wherever we are, wherever we go.

Particularly noteworthy is the wood, which creates an atmosphere of coziness and comfort everywhere. Metal and stone are colder and more laconic, but wood is even warm to the touch. That is why the first two materials are used more often in the form of load-bearing structures, and wood is used in interior decoration, however, after being brought into the appropriate form.

Before you cut a log , you need to inspect it. If there are no significant flaws on the outside of the tree, then processing can be done quickly and with virtually no loss of wood.

Logs must be sawed in such a way that the resulting materials have equal density. And to do this, you need to remember that the wood on the north side of the trunk has a higher density than on the south. Cutting a log lengthwise begins with removing the slab; this part is removed from both sides of the tree to create a beam that will not roll.

We place the resulting timber on one cut side, and the other looks up, and the cutting will begin from there. Now you can cut the remaining log into appropriate lumber or boards of equal thickness. The result is a set of unedged boards, in which the raw edge (sometimes even with tree bark) must then be cut with a handsaw. Now we can consider the work completed.

READ How to Cut a Gas Block Along

how I sawed a log into boards with a regular chain / Cutting lumber with a chainsaw simple chain

DIY device for sawing logs with a chainsaw

If desired, any such device can be made independently.

The first thing you will need is sawhorses to secure the log. Then the attachment frame and guide.

Making sawhorses for logs is not difficult. The main requirement is their height. Measure in advance the height that is comfortable for you so that you do not have to bend too low to the log or, conversely, work with your arms extended upward.

Making a frame attachment will require more knowledge and skills.

First you need to draw a drawing of the future frame, respecting the scale. Then, from a square pipe with a cross-section of 20×20 millimeters, weld the frame of the future device and weld the clamping elements onto it. It is necessary to make several holes in the cross member for bolt ties.

As strange as it may sound, the most common difficulty in making a do-it-yourself device for a rip saw chainsaw and other similar devices is the lack of welding. Therefore, before you begin, consider whether you have everything you need.

Presentation on technology on the topic “Sawing with a hacksaw” (grade 5)

Description of the presentation by individual slides:

Sawing wood Concepts: sawing, saw, teeth, cutting edge, miter box Yasskaya L.B., Municipal Educational Institution Secondary School. Krasnoturinsk

The log can be sawed lengthwise and crosswise manually or on special machines - sawmills. Sawing. one of the main carpentry operations

Sawing in industrial enterprises is carried out on circular sawing machines. Machine saw operators who operate these machines must be able to prepare them for work, cut material economically, and know what requirements the finished product must meet.

What tool is used for hand sawing wood? Blade Handle A carpenter's saw is used to cut wood by hand

What other tools are used to cut wood? Bow saws Circular saw For more precise sawing of thin pieces of wood or plywood, saws with fine teeth are used. Jigsaw

Based on the direction of cutting wood fibers, a distinction is made between transverse and longitudinal sawing. When cross-cutting, the cutting direction is perpendicular to the grain. When longitudinal sawing, the cutting direction is parallel to the grain.

By what other characteristics are saws distinguished? For cross-cutting, saws with straight teeth are used, and for mixed sawing and longitudinal sawing, with inclined teeth.

Cross-cutting When sawing across the grain, the workpiece is secured in a rear clamp or a backing board is used. The workpiece must be clamped so that it is located almost horizontally, and the cut point is located at the clamp.

Longitudinal sawing The rules for sawing wood along the grain have the following differences: 1) the working posture is slightly different than when cross-cutting 2) the body position is straight 3) the rhythm and pace of sawing is faster

The backing board is used to protect the workbench from cuts.

Sawing with a bow saw A bow saw is similar to a bow, that's why it's called that. Bow saws come in different designs. These saws are designed for rip and cross cuts, depending on the shape of the teeth, just like hacksaws. Do not forget that the quality of the sawn workpieces depends on the accuracy of the markings and the accuracy of your work.

READ Hand Saw For Cutting Logs

Fastening workpieces When sawing workpieces, special attention is paid to their reliable fastening. Before sawing, you need to make a cut using a block. This will protect your fingers from injury. When cutting a cut, use any block, which is held firmly with your left hand so that the end of the block is aligned with the marking line of the cut.

When sawing, the saw blade rubs against the walls of the separated parts of the wood. And so that it does not get pinched in the cut, the saw teeth must be set apart (tooth set), that is, alternately bent in different directions. This makes the cut a little wider and makes sawing easier.

Wires come in different forms. The figure below on the left(a) shows the main types of wiring. In figure b and c. shows correctly set teeth for transverse (b) and longitudinal sawing (c).

This is how they work with a hacksaw. The marked workpiece is placed on a board (1) on a carpentry bench that has a stop (2). With your left hand you press the workpiece against the stop, and with your right hand you make a cut. In this case, the hacksaw is pressed against the stop and several short smooth movements are made towards you. After sawing, the hacksaw is moved along its entire length, aligning it with the marking line of the cut. By moving the saw along the line, an incision is made, then the block is removed and the part is sawed off. At the end of sawing, the pressure on the saw is eased so as not to break off the wood fibers at the exit of the saw.

Square The quality of sawing can be checked using a square. While sawing, constantly check the sawing line with a square

Miter box Often there is a need to cut bars and boards at different angles. A miter box is used for precise sawing.

What device is used to accurately cut a block? For precise sawing of bars at angles of 90, 60, 45, a miter box is used. A miter box is a saw box with cuts in the side walls made at certain angles.

The miter box has a grooved shape. It consists of a bottom 1, two sidewalls 2, between which the workpiece to be cut 3 is clamped. The sidewalls have cuts made at the desired angle. Saw blade 4 is inserted into these cuts and sawing is performed at the desired angle.

The use of a miter box eliminates marking of the part, increases the accuracy of sawing, reduces the time spent on marking the part, thus increasing labor productivity. The use of a miter box is especially effective in the mass production of parts. The miter box may look like the one shown in the photo.

For ease of sawing, tsulaga is used. Tsulaga is very quickly made from a sheet of plywood or board and two bars. Thanks to the lower bar, it is easy to press it to the tabletop, and the upper one serves to support the workpiece. The tsulaga can be made with a movable stop for sawing off a large number of identical parts.

What devices are used when cutting (notching) a cut? When cutting (notching) a cut, a stop or block is used.

Sawing plywood Plywood blanks are easier to saw by changing the sawing angle. The smaller the cutting angle, the better the cutting will be done.

Wires come in different forms. The figure below on the left(a) shows the main types of wiring. In figure b and c. shows correctly set teeth for transverse (b) and longitudinal sawing (c).

Safety rules: Securely secure the workpiece when sawing. To guide the canvas, use wooden blocks and special stops. Use stops, miter boxes and other devices. Sawing only with a serviceable, sharply sharpened saw. Do not allow the saw to skew when sawing. Do not make sudden movements with the saw. Do not keep your left hand close to the saw blade. At the end of sawing, release the pressure so as not to chip the wood fibers. Place the saw on the workbench with the teeth facing away from you. Do not blow away sawdust or sweep it away by hand. Use only a brush.

Remember! When sawing workpieces, the markings retreat from the mowing line by 2-3 mm. The hacksaw blade should move at right angles to the workpiece. Sawing control is carried out along the markings of the mowing line. It should remain to the left of the sawing point on the workpiece.

Practical work Tools and materials: Blank, square, ruler, pencil, hacksaws, miter box. Procedure: Practice sawing techniques on waste material. observing safety regulations. We cut wooden blanks to the given sizes. We drank the preparation in a miter box.

Gift certificates

Responsibility for resolving any controversial issues regarding the materials themselves and their contents is taken by the users who posted the material on the site. However, the site administration is ready to provide all possible support in resolving any issues related to the operation of the site. If you notice that materials are being used illegally on this site, please notify the site administration using the feedback form.

All materials posted on the site were created by the authors of the site or posted by users of the site and are presented on the site for informational purposes only. Copyrights for materials belong to their legal authors. Partial or complete copying of site materials without written permission from the site administration is prohibited! The opinion of the administration may not coincide with the point of view of the authors.

Sources:

https://zodchi42.ru/brjovna/kak-raspilit-brevno-vdol-vruchnuju.html https://superarch.ru/materialy/kak-raspilit-brevno-vdol-benzopiloj https://infourok.ru/prezentaciya- po-tehnologii-na-temu-pilenie-stolyarnoy-nozhovkoy-klass-502591.html

Safety regulations

Important to remember:

- Do not use a chainsaw if you are sick or under the influence of alcohol.

- Hold the chainsaw firmly with both hands to ensure full control of the tool during unexpected jerks.

- Hands should be clean and dry to ensure a secure grip on the tool.

- Only use the chainsaw on a stable surface with sufficient surface area.

- Do not operate the chainsaw with your arms raised or extended.

A way for those who like to cheat

And finally, there is a way to cheat and instantly get a sawn log. Skyrim, as you know, is not without cheats, one of which will allow you to acquire the necessary amount of any resource.

To get a sawn log, you need to enter the command “player.additem XX00300e” in the console. Here, instead of “XX”, you should substitute a number from 01 to 04, indicating the installation order of the Hearthfire add-on. Most often the value you need will be 04, but if the cheat doesn't work, you can try other numbers.

Thus, you can receive logs in unlimited quantities and at any time, and you will not spend precious gold on this. But don’t forget that using cheats spoils the fun of the game, so try to use them as rarely as possible.

Sawing process

It includes the following steps:

- Place the log on the sawhorse.

- Attach the frame to the tire.

- Attach the supports that are designed to hold the ruler, making sure that they are installed exactly level.

- Secure the fasteners with self-tapping screws (they will be easier to remove after finishing the work).

- Make sure that the cut line will be 1 centimeter above the ruler, and not along it.

- Make the first cut.

- Release the log from the stops and move the fixture to the next cutting line.

- Next, you can remove the ruler and continue to focus on the cut you made earlier.