Working with viscous mixtures

If you plan to use a screwdriver for mixing mixtures, then it is better to purchase a device with high power.

Simple household models will find it difficult to complete this task. Mixing requires high torque, which is present only in professional devices. You can additionally use mechanical built-in gearboxes; they will allow you to get high-quality results even in the first mode. A cooling system is also provided in advance to avoid the possibility of motor failure. For everyday screwing of shelves or securing cornices, a powerful screwdriver is not required; for these tasks, torque is not important. But if you need to frequently use a screwdriver for several types of tasks, you should opt for a professional or semi-professional model.

When purchasing a screwdriver for home use, several factors and parameters are taken into account. They decide in advance whether a professional model is needed, or whether a simple household tool can be used. This will help you plan your budget. Then you will have to study the functionality of the selected device, technical characteristics

Focus on torque

Which torque is best?

A screwdriver is a tool that is necessary for carrying out various types of work. This is not only construction, but also many home repairs, such as furniture assembly and communications installation. To select the right equipment, you should pay attention to the torque, which determines the comfort and quality of work. For example, you don’t need a very powerful tool to assemble furniture. If you plan to install an interior partition, then you need to take more professional equipment that will cope with the task perfectly.

Drills and screwdrivers are used to mix construction mixtures; you just need to purchase a construction mixer attachment.

The torque of such tools must be sufficient to allow mixing even the most viscous mixtures and solutions, ensuring their uniformity and high quality.

Special attachments are used for mixing concrete and other viscous mixtures.

If you need to use nozzles for mortars, then the torque must be sufficient to cope with mixtures of not only low viscosity, but also high ones. The choice of model depends on the planned work. If you need to use a screwdriver for mixing liquid mixtures, then the torque may not be too high. If a tool is purchased to work with viscous mixtures, then it is necessary to prefer professional devices whose speed is high.

Equipment that will be used for a variety of work must have a speed regulator. Then the torque can be changed depending on what type of work needs to be performed. When choosing a screwdriver, you need to make sure that the lock for the control button always works, and not just with maximum force. In the first case, the tool can be used for any job under the most convenient conditions. The torque value can be changed. It is recommended to buy models that have manual or electronic control. They have a special step-down transformer that works great with liquid mixtures when the voltage drops.

Power type and characteristics

According to the type of operation, the tool is divided into battery-powered and mains-powered.

A screwdriver connected to a power outlet is convenient because you don’t have to recharge the battery at the most inopportune moment, but working with it is often very inconvenient because the wire gets in the way. Such models can be compared to an electric drill, but with a special torque regulator. Adjusting the torque is convenient, for example, when installing drywall , when you need to gently tighten the screw after its head comes into contact with a sheet of drywall, without breaking through it.

Standard equipment for a cordless screwdriver: screwdriver, 2 batteries, charger, flashlight, 1 set of bits with a magnetic holder, plastic suitcase.

A tool with a battery is convenient to use in the most difficult places, but can run out of power at the wrong time.

Types of cartridges

When choosing a tool, you should definitely pay attention to the type of chuck. It can be three-jaw or six-jaw

The size or diameter of the chuck is also of considerable importance: the larger the diameter, the more functions the tool can perform.

Torque

Torque will tell you how to choose the right screwdriver. In electrical equipment it can be hard or soft and is measured in newtonometers. When choosing, take this indicator into account: the higher it is, the better the quality of the tool.

The soft torque is responsible for tightening and unscrewing parts and can range from 0 to 350 rpm, while the hard torque is responsible for drilling and varies from 0 to 1000.

Reverse

Reverse, or reverse motion, is very convenient to use, and its presence is desirable among the functions and characteristics of the tool. Reverse allows you to not only screw in, but also unscrew screws, and will also be useful in a situation where the drill gets stuck in wood, brick or any other material.

On an instrument with reverse, not far from the start button there should be a through button, pressing which turns the reverse on and off at any time convenient for you.

Please note that the reverse button is comfortable for you and easy to press

Having the following characteristics will help you choose a good screwdriver at your discretion. They do not play a major role when working with the tool:

- the presence of an impact mechanism that allows you to work with socket heads and with concrete and brick;

- possibility of torque control;

- several speed modes will allow you to work with a screwdriver like a drill with an increase in the number of revolutions per minute;

- the presence of backlight will help when working in corners or dark rooms;

- battery capacity: any electrical equipment capacity is measured in amperes per hour, that is, the more amp hours in the battery, the longer it will work without recharging.

http:

How to extend battery life?

You can extend the life of a screwdriver without purchasing a new battery; to do this, follow a number of conditions and simple rules:

- Charge the battery only in rooms with positive temperatures. Charging in the cold will quickly damage the tool;

- as soon as the battery is low, remove it from the tool and let it sit for at least 10 minutes, only after that it can be recharged;

- Do not charge the battery a second time if no work has been done during this time.

Dependence of the magnitude of the rotating force on the size of the working screw

The operation of a screwdriver can be analyzed by the ratio of torque and screw diameter. It is not difficult to determine the correspondence of the amount of force applied to the size of the fastener. The dependency will look something like this:

- a screw diameter of 6 mm when working with soft materials corresponds to a torque of 10 Nm (newtonmeters), while screwing a self-tapping screw into hard and rigid surfaces will require a force of 25 Nm;

- using a screw with a diameter of 7 mm in soft materials will require a force of 11 Nm, while in hard materials it will increase to 27 Nm;

- screwing in screws with a maximum diameter of 8 mm will require a torque of 14 Nm for soft materials, and 30 Nm for hard materials.

Such an analysis will not only improve the efficiency of using the tool, but will increase its reliability and service life.

Torque for gasoline and diesel engines

Gasoline engines do not have the highest torque. The torque of a gasoline engine reaches its maximum value at speeds of no less than 3-4 thousand rpm. However, a gasoline engine can quickly increase power and spin up to 7-8 thousand rpm. At such ultra-high speeds, power increases significantly.

The diesel engine does not have high speeds. Usually this is 3-5 thousand rpm maximum, and here it loses to gasoline engines. However, the torque of a diesel engine is several times higher, and it becomes available very quickly, almost from idle.

As a specific example, we can recall tests of two engines from Audi - one diesel: 2.0 TDI with 140 hp. and a torque of 320 N.m, and the second petrol: 2.0 FSI with a power of 150 hp. and torque 200 N.m. Based on the results of a test run in various modes, it turns out that the diesel engine is as much as 30-40 hp. more powerful than a gasoline engine in the range from 1 to 4.5 thousand revolutions. That's why you shouldn't look only at horsepower. It happens that an engine with a smaller displacement, but with high torque, shows itself to be much more dynamic than an engine with a large displacement, but low torque.

In the technical specifications that are indicated for each car and its engine, the maximum torque is always indicated in combination with the speed at which such torque can be achieved. In this case, it is usually considered: if the maximum torque can be achieved at speeds up to 4.5 thousand rpm, then such an engine can be called low-speed; and if more than 4.5 thousand rpm - then high-speed.

At a low number of revolutions, a small amount of air-fuel mixture enters the combustion area per unit of time, so torque and power are low. By increasing the speed, the amount of the fuel-air mixture (and subsequently the power and torque) increases. Having reached significant parameters, power begins to decrease due to mechanical losses due to friction of mechanisms; inertial losses; from insufficient air injection (called oxygen starvation).

To ensure maximum amounts of air entering the combustion chamber, even at low engine speeds, electronically controlled turbocharging systems are used. By using such turbocharging systems, it is possible to ensure uniform torque characteristics over a wide range of engine speeds.

Torque is the main criterion for choosing a power tool

Guided by this parameter, they choose a tool for home or production. For household and semi-professional screwdrivers, the rotating action should be from 5 to 15 Nm. This indicator allows you to easily cope with screwing in tight self-tapping screws and drilling holes in metal and concrete surfaces.

The magnitude of the torque action is determined depending on the characteristics of the upcoming operations and the physical properties of the materials. If you plan to work with metals, alloys and hard structural polymers, then it is more advisable to choose a universal semi-professional screwdriver with high torque and a spindle speed of up to 1300 rpm. When working only with wooden workpieces, a household appliance with a speed of 500 rpm is quite sufficient.

Device screw diameter ratio

Let's consider the relationship between the rotation speed of the drill and the diameter of the screw used in the device:

- with a maximum screw diameter of 6 mm, the rotation speed when screwing is 10 Nm for structural soft materials and 25 Nm for structural hard materials;

- with a maximum screw diameter of 7 mm, the rotation speed for interaction with soft materials is 11 Nm, and for working with hard materials - 27 Nm;

- with a maximum screw diameter of 8 mm, the torque of the drill when interacting with soft structural materials is 15 Nm, and with hard ones when screwing - 30 Nm.

Diagram of the hammer drill device.

The ratios show how it is possible to use working screws of the required size at a certain torque. This makes the work more efficient, but it must be remembered that when using screws with a small diameter, the duration of the operation increases. There are some peculiarities when working with large-diameter screws: the batteries of such equipment run out quite quickly. Therefore, choose models with a larger battery if you want your power tool to work for as long as possible without tiring recharging, or purchase a kit with a spare battery.

There is another very useful characteristic - reverse motion. This function allows you not only to free a suddenly stuck drill, but also to quickly unscrew a tight self-tapping screw. Reverse (reverse) for most is electronic: switching is carried out by changing the so-called electrical polarity. To control the reverse, a two-position switch is provided; it is located next to the tool start button.

Rotational speed and screw diameter

When buying a screwdriver, you need to separately evaluate the ratio of the screw diameter to the rotation speed. To do this you need to know that:

- For screws with a diameter of 6 mm, the rotation speed when tightening will correspond to 10 Nm. Moreover, this indicator may vary depending on the hardness of the material. So in some cases it can reach up to 25 Nm.

- If a screw with a diameter of 7 mm is used, then the torque will be 27 Nm for hard materials and 11 Nm for soft materials.

- With a screw diameter of 8 mm (the largest value), the torque reaches 30 Nm.

A correctly selected torque indicator will allow the technician to quickly complete the necessary work. Such a tool will last longer and be less likely to fail. The higher the torque, the less force the master has to apply.

Torque power is not so important for a powered tool. But for cordless screwdrivers, this is a very important parameter, which determines how quickly the battery will drain.

Subscribe to TechnoCouncil on social networks so you don’t miss anything:

Basic parameters of the battery and the tool itself

The main parameter that characterizes the operation of a screwdriver is the battery voltage, which, in turn, determines the electric motor power and torque. For household models, the difference in voltage between screwdrivers is small - on average, it is in the range of 10.8–14.4 V. More productive options intended for constant use can be equipped with 24–36 volt batteries.

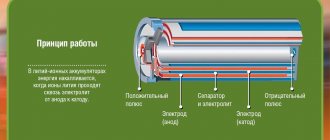

The battery voltage of a screwdriver also depends on the type of battery - you can answer what the difference is by knowing what metals were used to make it. For nickel-cadmium batteries, large in size with a similar capacity, the value of the indicator is a multiple of 1.2 V (this is exactly the voltage of one element that makes up the battery pack), for lithium-ion batteries - 3.6 V.

Other equally important characteristics include:

- the power of the screwdriver, which can also be used to determine the speed of tightening screws and self-tapping screws. To carry out repairs on your own, models with a performance of 500–700 W are sufficient. A professional repairman will need more powerful equipment - 800–850 W;

- the number of revolutions of the rotating part of the device per unit time. This parameter determines whether the screwdriver can perform the task assigned to it - for example, tighten the required type of fastener. So, for a bolt, self-tapping screw and screw, 500 rpm is enough, for drilling you will need 1200 rpm;

- torque, the value of which can be one of the main answers to the question of what the voltage of the screwdriver battery affects. Using this characteristic, you can determine both the diameter and the length of the screw or self-tapping screw being screwed. Large fasteners, as well as drilling deep and wide holes and hard materials, require significant torque. The maximum value of the indicator is 10–60 Nm.

There are two types of torque for screwdrivers - starting (larger in magnitude and required to put the device into operation) and constant, that is, working. The parameter value for modern equipment models can be adjusted - you can find out how many modes can be selected for a particular device in the documentation available for it. Moreover, tools with a pulse mode of operation (turning on the rotating part in jerks) have more screwing capabilities - allowing them to periodically increase the torque, they can screw in a larger screw.

In addition to the voltage of the screwdriver and its power, the battery capacity should also be assessed. The characteristic is measured in ampere-hours or milliamp-hours. The higher the indicator, the longer the screwdriver can work without recharging.

The average battery capacity of a household model is 1300 mAh, which is enough for 2–3 hours of operation. Professional equipment requires more time to complete the work - and a master who uses a screwdriver throughout the whole working day should purchase a model with 1.5–2.0 Ah batteries.

Practice

For practical exercises, we took three different screwdrivers and two different types of screws/screws and will screw them into a dry pine beam, simultaneously recording the success of the operation and the time spent.

Here are the names of screwdriver models and their brief technical characteristics:

| DeFort DCD-12-6 | Bosch PSR 960 | Hitachi DS 14DCL | |

| torque, Nm | 10 | 12 | 31 |

| rotation speed, rpm | 0-500 | 0-550 | 0-450 0-1250 |

| battery | Ni-Cd, 12 V, 1.2 Ah | Ni-Cd, 9.6 V, 1.2 Ah | Li-ion, 14.4 V, 1.5 Ah |

It’s no coincidence that two “old guys” (Bosch and DeFort) ended up here. These low-power models will immediately make it clear how correct the entire theory stated above was, and whether absolutely any screwdriver is enough to successfully work with 5x90 mm self-tapping screws and the like. And the average Hitachi will simply complement our picture and play the role of some kind of modern instrument.

Regarding the screws, we did not waste time and took a thin black 4.8 x 127 mm and, for completeness, a powerful white 6 x 150 mm for testing. To screw the latter into a pine beam, presumably, a maximum torque of about 11 Nm is required.

So, as a summary, we invite you to watch a short video in which we captured the entire process.

A thin self-tapping screw (4.8 x 127 mm) turned out to be a feasible task for all screwdrivers, without exception, although it was clear that it was not so easy for Bosch. The time taken by the screwdrivers was: 5.3 seconds for DeFort, 7 seconds for Bosch and 2.9 seconds for Hitachi. We did not set the task of accurately comparing time and repeatability; only the final result was important to us. That's why we made only one take for each of the models.

The white “strong guy” was no longer too tough for everyone. As in the previous case, DeFort started very vigorously, but the last centimeter did not submit to him.

Bosch, although it solved the problem, the smell of burnt windings made it clear that such loads are strictly contraindicated for this tool.

Well, for the powerful Hitachi, both self-tapping screws are like toys. Here's what the stopwatch showed: 13.3 seconds for DeFort (missed 1 cm), 20.7 seconds for Bosch and 4.3 seconds for Hitachi. In addition, we note that during the test Hitachi worked at the second speed, where the torque was at least a third lower than the maximum stated in the characteristics.

We have one more important note regarding the practical part: our test involved screwdrivers of older models (Hitachi does not count), which do not have an overload protection system. Most modern models have such a system, so they will not allow you to abuse the tool as much as can be seen in the video with a Bosch screwdriver. This also means that the security system will not allow such a screw to be screwed in completely the first time. You will have to turn on the tool several more times until the protection is triggered again (usually 1-2 seconds) until the screw is tightened. But in order not to abuse the tool like this, of course, you need to buy a screwdriver with a certain power reserve!

What is the torque of a screwdriver?

When familiarizing yourself with the characteristics of any screwdriver, you will definitely come across such a parameter as torque, which is measured in newton meters (Nm). Not everyone remembers from school physics what this means. And in this article I will try to explain what the torque of a screwdriver is.

In simple terms, the torque of a screwdriver means the maximum force that it can transmit to the screw or screw being driven. It is clear that the higher the torque, the greater this force will be.

What does all this affect? On how large, for example, a self-tapping screw or a screw in length and diameter can you screw into a particular material. Well, besides, if you take two screwdrivers with different torques and do the same job with them, then the mechanism of the screwdriver with more torque will wear out less. Therefore, we can say that the amount of torque also affects the service life of the tool.

What is torque

Torque is a technical characteristic that indicates the loading force of a tool. On average, this figure fluctuates around 5-10 Nm, which allows the master to solve various technical problems.

This load is typical for household and semi-professional screwdrivers. This rotational force is enough to screw in bolts and screws, mix mortar, and drill metal plates of medium thickness.

What torque tool will work best for most problems? The answer to this question depends on where and how you intend to use the tool. For example, if the user requires a universal device that can be used to perform different jobs. Then it is better to purchase a tool with maximum rotation force. Such a tool can screw self-tapping screws of any length, even into hard materials (metal, hardwood, plastic).

Screwdriver torque

If a user purchases a screwdriver to work with ordinary wood, a tool with a minimum rotation rate will suit him. Even 500 rpm machines can drive screws. For more complex surfaces, it is better to choose a tool with a speed of 1300 rpm. This screwdriver can drill into the toughest materials.

How to choose a screwdriver

A screwdriver is a universal power tool, used for tightening fasteners and drilling not very hard materials: wood, plastic, drywall, thin sheet metal, etc. Non-standard use of a screwdriver is drilling holes in ice during winter fishing and mixing not very thick building mixtures.

A screwdriver is considered a multi-purpose tool, as it is used in different types of work: repair, finishing, grinding surfaces, assembling furniture and various structures, working with drywall, wood, etc. The device can be used both indoors (in an apartment, in a country house, in a garage ), and outside.

The design of any screwdriver is the same: an electric motor with a gearbox that transmits rotation to the spindle and equipment, a chuck of a certain type and an electronic control system. There is also a torque-regulating clutch and a battery (for cordless models) that powers the tool. Choosing the best tool for your needs requires careful consideration. Our article will tell you which screwdriver to buy for home or professional use.

Screwdriver models

A screwdriver is the most commonly used tool, which is indispensable for construction and repair activities. Today, manufacturers offer a variety of models that can be used under various conditions. This tool is convenient for manual work; it is necessary for tightening/unscrewing screws, screws, self-tapping screws, for drilling and even for stirring building mixtures.

According to the power source, the tool is classified into:

The cordless screwdriver is powered by a battery included in the kit.

- Rechargeable models powered by special batteries. They increase the weight of the tool, but make work more convenient in hard-to-reach places.

- Network devices that require connection to an electrical network. They have a limited range of action due to the length of the cord, although extension cords can be used.

By purpose, equipment can be divided into:

- models for construction/repair work;

- for production shops, workshops, auto repair shops;

- for industrial enterprises;

- for household use.

There are professional, semi-professional, and household models on sale. When choosing, you should pay attention to the torque, which shows what kind of work the screwdriver can handle.

Which screwdriver is better, corded or cordless? Characteristics

When choosing an electric screwdriver, you need to pay attention to many characteristics. After all, you need a high-quality tool that will make doing any job more comfortable and easier.

Therefore, be sure to review the following options:

- power;

- torque;

- rotational speed;

- reverse;

- presence of a smooth speed controller;

- possibility of fixing the power button.

Now we will talk about each of the points in more detail, so that even a not very experienced master can understand them.

Everything is clear with power - the higher it is, the greater the energy consumption and functionality. Most models have power from 100 to 900 watts.

Of course, more powerful ones cost more and are larger. However, it doesn’t always make sense to buy an expensive model - professionals usually work with them.

A 400–500 W screwdriver will be sufficient for a home craftsman.

By using torque, you can determine the force with which the bit acts on the screw. Accordingly, an electric screwdriver with a high torque effect will be able to screw screws into hard materials. The torque can range from 10 to 100 Nm. For most models, 20–25 Nm is enough.

Important! Many buyers wonder which screwdriver is better: corded or cordless? The first is noticeably lighter, cheaper and more durable. But the second one makes it possible to remain autonomous and not be tied to an outlet

Rotation speed is not the most important indicator. If you plan to use the tool simply for tightening screws and self-tapping screws, then you can choose the cheapest one

What difference does it make whether the screw takes 0.5 or 0.1 seconds to tighten? If you are looking for a high-quality drill or renovator with a screwdriver function, then you should pay attention to this parameter. High rotation speed results in a smoother hole

Reverse is a rather useful function, so it is desirable that it be present. Thanks to it, you can not only tighten screws, but also unscrew them. The main thing is to make sure that the switch button is comfortable.

Do you have to work with different materials - chipboard, boards, brick, concrete and others?

Then a smooth regulator will be indispensable - thanks to it you can configure the tool to work with a specific material.

But if you take out a screwdriver once every few months, then it’s easier to choose a model whose speed is controlled by the force of pressing the button.

But fixing the power button is a rather controversial function. Of course, it’s convenient that you can turn on the tool and no longer press the button. On the other hand, if the tool is run for several minutes without switching off, it will cause overheating and will seriously affect the service life.

Using this knowledge will greatly facilitate the process of choosing a quality tool that will serve you for many years.

You may be interested in information about how to work with a hand router on wood.

What is meant by torque?

Cordless screwdriver device.

Torque is a value that allows you to determine the level of load on the equipment. Which option should I choose? It is usually equal to 5-10 Nm, this is quite enough for safe and high-quality operation of the tool. This option is provided for most household and semi-professional models, which can easily cope with tight screws, drilling steel, and concrete.

What should the torque be? You should pay attention to what the tool will be like. For example, for a universal device, it is necessary to select fairly high torque values so that the tool copes equally well with any type of work, be it self-tapping screws or structurally rigid materials. If you only need a tool for drilling wood, then you may prefer a model with a small torque from among household ones. When choosing, you should pay attention to the number of revolutions. For example, 400-500 is quite enough for screwing self-tapping screws. For drilling hard surfaces, it is best to use devices with a speed of 1200-1300 per minute .

Household or professional?

Before going to the store, or on the way to it, think about what kind of repair or construction work you need this tool for. And based on your conclusions, you need to make a choice of a screwdriver according to the parameters. If you are not a keen home craftsman and you only need to take out the device a few times a month, then why should you buy a professional model, which will cost several times more. After all, you must admit that an amateur model that runs on battery will be enough for you. It will have all the necessary functions, and the household model will weigh significantly less than the professional one.

However, when you need to twist, build or assemble something almost every day, then you need to pay attention not to cheap household models, but to more expensive, but extremely powerful models for professionals. They are most often powered from the mains, and also have greater weight and size.

It makes sense to buy such corded drill and screwdrivers for those who have large volumes of work with increased loads on the tool. And how to choose a network design screwdriver also needs to be studied.

Torque: how much is needed for construction

Another parameter that affects the functions of the tool is torque. It is measured in Newton meters (N*m). Thanks to the torque, you can determine the degree of load for which the drill/driver is ready. The higher the torque, the greater the range of work the tool can perform.

For home work, a drill-driver with a torque of 10-15 N*m is suitable, when working with dense materials (for example, when screwing a 100 mm self-tapping screw into wood) - 30-40 N*m. Professional builders are recommended to use a drill/driver with a torque of more than 120 N*m.

Household or professional

As you know, professional screwdrivers are more expensive, but this is no coincidence. They are made with a large margin of safety, for which higher quality and more expensive materials are used. In addition, they have more power, which makes it possible to screw in longer screws and/or work with tougher materials.

The difference between a professional and household screwdriver in resource

To decide whether you need a household or professional screwdriver, assess the amount of work that will need to be done. If you are starting construction or major renovations, you probably need a professional or semi-professional model. If you need a tool periodically to unscrew/tighten something from time to time, a household tool is more than enough. With such work, the professional tool resource simply will not be in demand. So choosing a screwdriver based on this criterion is not very difficult.

Torque - what is it?

Step adjustment

Torque is an indicator with which you can set the load force on the screwdriver.

It is usually in the range of 5 to 10 Nm, which allows you to get the job done quickly, efficiently and without problems.

This load is used for household and semi-professional models.

It easily drills through metal plates, screws in large screws, and also works with concrete.

How much torque does a screwdriver need to work well? This is determined by the purpose of the tool. For example, for a universal device it is better to choose the maximum indicator. This will allow him to work equally successfully with self-tapping screws and hard materials.

If a screwdriver is purchased for drilling wooden blocks, then the cheapest household model with low torque will do. For example, 400-500 revolutions can easily tighten a self-tapping screw. But to drill holes in hard surfaces, you need to select a speed of 1200-1300 per minute.

How to Check the Torque of a Screwdriver

What is the torque of a screwdriver

The torque of a screwdriver is a significant parameter that you need to pay attention to when choosing. It is necessary to take into account whether the tool will be used for home or professional work.

There are a variety of models on sale today that differ in their characteristics.

The construction market offers many models of screwdrivers from various manufacturers, which differ depending on the power source, parts and functions.

Screwdriver models

A screwdriver is the most commonly used tool, which is indispensable for construction and repair activities. Today, manufacturers offer a variety of models that can be used under various conditions. This tool is convenient for manual work; it is necessary for tightening/unscrewing screws, screws, self-tapping screws, for drilling and even for stirring building mixtures.

According to the power source, the tool is classified into:

The cordless screwdriver is powered by a battery included in the kit.

- Rechargeable models powered by special batteries. They increase the weight of the tool, but make work more convenient in hard-to-reach places.

- Network devices that require connection to an electrical network. They have a limited range of action due to the length of the cord, although extension cords can be used.

By purpose, equipment can be divided into:

- models for construction/repair work;

- for production shops, workshops, auto repair shops;

- for industrial enterprises;

- for household use.

There are professional, semi-professional, and household models available for sale.

When choosing, you should pay attention to the torque, which shows what kind of work the screwdriver can handle.

What is meant by torque?

Cordless screwdriver device.

Torque is a value that allows you to determine the level of load on the equipment. Which option should I choose? It is usually equal to 5-10 Nm, this is quite enough for safe and high-quality operation of the tool. This option is provided for most household and semi-professional models, which can easily cope with tight screws, drilling steel, and concrete.

What should the torque be? You should pay attention to what the tool will be like. For example, for a universal device, it is necessary to select fairly high torque values so that the tool copes equally well with any type of work, be it self-tapping screws or structurally rigid materials

If you only need a tool for drilling wood, then you may prefer a model with a small torque from among household ones. When choosing, you should pay attention to the number of revolutions. For example, 400-500 is quite enough for screwing self-tapping screws. For drilling hard surfaces, it is best to use devices with a speed of 1200-1300 per minute.

Torque to screw diameter ratio

When choosing a cordless or corded screwdriver, it is important to correctly determine the ratio of screw diameter and rotation speed. This dependence is not too difficult to determine:

Test of Dnipro-M screwdrivers. Wrapping moment

In this test of screwdrivers, we verified the torque of 8 screwdrivers of the Dnipro-M brand. For whom, for the skin.

Why do you need a ratchet on a screwdriver?

Or torque

To tighten screws of different diameters, different rotation speeds are required.

- If the diameter of the screw is 6 mm, then the rotation speed during screwing will be 10 Nm. For materials that are structurally soft or hard, the frequency will be 25 Nm.

- If the screw diameter is 7 mm, then the torque when working with hard materials will be 27 Nm, and for soft materials - 11 Nm.

- With a maximum screw diameter of 8 mm, the torque will

be 30 Nm.

What does this ratio show? It is possible to determine exactly what torque can be used for a certain diameter of the working screw. The right choice will not only make the work more efficient, but also increase the quality, reliability, and durability of the equipment. The operation will be completed much faster and the operator will spend less effort.

Torque: Definition

Equipment can be divided into professional, semi-professional and household. In accordance with the purpose of the tool, it is worth choosing its characteristics. Everyone knows about the power and speed of spindle rotation. Let's look at an equally important parameter of a screwdriver - torque. This is an indicator that determines the amount of rotational force on the body.

Better models for home and “gangs”

Makita DF033DZ

A small pistol model from a Japanese manufacturer is suitable for performing infrequent work on tightening/unscrewing screws, as well as for drilling holes in wood and metal. It can drill a maximum of 21 mm in wood, and 10 mm in metal. At the same time, it copes with self-tapping screws of 50 - 60 mm with a bang, thanks to a torque of 30 Nm. The torque can be adjusted in 21 positions. We also note that the user can set the chuck rotation speed to 450 and 1700 rpm depending on the material he is working with.

There is good illumination for working in hard-to-reach places or where there is poor lighting. The device weighs only 930 grams (without battery), so you can work with it for quite a long time without fatigue in your hands. We also note the relatively low cost of the unit. This device does not come with a battery, so you will have to purchase it separately. It is suitable for batteries of types BL 1015, 1016, 1020V, 1021V, 1040V, 1041V.

Bort BAB-12X2LI-FDK

Another inexpensive “hard worker” that will work flawlessly for many years. It has a torque of about 35 Nm, which allows it to drill 10 mm holes in metal and 25 mm in wood. If desired, you can adjust the rotation speed of the chuck in two positions: 350 and 1350 rpm. And to better see the drilling site, there is high-quality lighting. After turning off the power, the engine stops immediately and you do not have to hold the device suspended while waiting for the bit to stop.

Note that the screwdriver comes with two replaceable 1.5 Ah batteries. On average, the battery is fully charged in an hour. It also comes with a double-sided bit and a convenient storage case. Overall, this is a great inexpensive consumer device for home repairs.

BLACK&DECKER BDCDC18K

This device belongs to the so-called class of drill-drivers, although it performs the same functions as a regular “Shurik”. It runs on a 1.5 Ah lithium-ion battery. By the way, it comes included, so you don’t need to buy it separately. If you want to purchase an additional battery, the following components are suitable for it: BL 1518, 2021 and 4018.

The device is capable of drilling holes measuring 10 mm in metal and 25 mm in wood. The maximum screw-in force of the screws is 30 Nm. It can be adjusted in 10 positions depending on the material being processed. As in previous models, there is illumination of the workplace. This device is supplied with a plastic case for transportation.

Bosch GSR 10.8 V-EC YX

This compact baby from the German company Bosch is designed for constant use at home and on social occasions. It is very light - only 700 grams, so it is perfect even for a woman's hand. There is a relatively small torque of 20 Nm, which is enough for fastening plasterboard and profiled sheet iron. Depending on the “delicacy” of the material, you can change the rotation speed of the cartridge using a switch.

The main advantage of the model is the brushless motor, which, with a low device power, provides excellent efficiency and eliminates the need for regular replacement of carbon brushes. If the unit overheats or its drill jams, the protective system will turn off the engine. As required from a high-quality device, there is illumination of the work area. Boshev's "Shurik" is not cheap, but you have to pay for German quality.

DeWALT DCF887N

Well, we couldn’t ignore the powerful impact screwdriver from DeWALT. This professional unit is designed for heavy-duty work on tightening/unscrewing screws and self-tapping screws. A torque of 205 Nm allows you to use the device as a wrench, which is useful during car repairs. At the same time, you can adjust the CM, adjusting it to materials of different densities. There is also a 3-position speed control.

Like the previous model, the DeWALT DCF887N is equipped with a brushless, durable motor. Three LEDs located on top of the body will provide high-quality illumination of the work area. Users note the excellent build quality - there is no play or creaking anywhere, the bat is held firmly in the chuck. However, the high quality of the device affected the price.

- Screw in completely: rating of networked screwdrivers 2019

- Pumping water: which pump to choose for a well?

Torque to screw diameter ratio

When choosing a cordless or corded screwdriver, it is important to correctly determine the ratio of screw diameter and rotation speed. This dependence is not too difficult to determine:

To tighten screws of different diameters, different rotation speeds are required.

- If the diameter of the screw is 6 mm, then the rotation speed during screwing will be 10 Nm. For materials that are structurally soft or hard, the frequency will be 25 Nm.

- If the screw diameter is 7 mm, then the torque when working with hard materials will be 27 Nm, and for soft materials - 11 Nm.

- With a maximum screw diameter of 8 mm, the torque will be 30 Nm.

What does this ratio show? It is possible to determine exactly what torque can be used for a certain diameter of the working screw. The right choice will not only make the work more efficient, but also increase the quality, reliability, and durability of the equipment. The operation will be completed much faster and the operator will spend less effort.

For network equipment, high power has little effect on the operation process, and batteries run out quickly. Therefore, it is necessary to have spare batteries and the ability to charge already installed ones. Typically, for professional tools, manufacturers provide spare batteries, but for simpler models, at least one battery will have to be purchased separately. When choosing a screwdriver, you need to take into account the presence of another function - reverse. It is necessary when the drill gets stuck in the material. This reverse is usually electronic; to control it, you should use a two-position switch, which is located near the start button.

Battery or mains

Having decided on the class, you will need to decide whether you need a corded screwdriver or a cordless one. The disadvantages and advantages of both are obvious: the battery-powered one has higher mobility and the cord does not interfere with operation, but it weighs more. The network connection does not depend on the presence of battery charge, but not all construction sites have power supply. In general, the choice is not easy. The decisive point may be that a cordless screwdriver with a good battery costs significantly more than a similar model operating from the mains. The difference is due to the presence of a battery - good options are not cheap.

For a corded screwdriver, the length of the cord is important

If you decide to choose a corded screwdriver, pay attention to the cable length. The longer it is, the more convenient it will be to work - you won’t have to carry a carrier either.

To choose the right cordless screwdriver, you need to pay attention to the type of battery. The duration of operation on one charge, as well as the order of storage, depend on this.

Lithium-ion (Li-lon). Holds a charge for a long time, charges quickly, has a large number of recharges, and almost never discharges during storage. In general, a good option, but expensive. Therefore, it is probably more common on professional models, where the duration of operation on a single charge is important.

Disadvantages include fear of cold, which is important in our country.

Nickel metal hydride (Ni-MH). This type of battery is environmentally friendly, small in size and weight, and has an average price. Disadvantages - they also do not like low temperatures, they have a short service life - about 3 years

But it’s easier to work with such a tool—the hand doesn’t get so tired. When storing the battery, the battery is fully charged; discharged batteries cannot be stored. During storage they are discharged, but moderately.

Nickel-cadmium (Ni-CD). The main advantages are low price and service life of 5 years (number of charges - about 3000), it is not afraid of frost, that is, you can work outside in winter. Disadvantages - it takes a long time to charge (it takes twice as long as charging other types of batteries), has a “charge memory”. Charge memory is a nasty thing. If you charge a battery that is not completely discharged, the total capacity of the battery will decrease. It will become smaller by exactly the value from which the charge began. Therefore, you need to work with such a tool until the battery is completely discharged, which is not always convenient: it cannot always “tighten” the screw, you have to help with your hands or tighten it with a “fresh” battery. Store completely discharged, otherwise the capacity will decrease again.

So, if you choose a cordless screwdriver for periodic work, a nickel-cadmium battery will do just fine. If you use it carefully, it will last a long time. If you are starting large-scale work, it is better to use other batteries - there will be less downtime, the work will move faster.

Torque parameters regarding the use of a screwdriver

The value depends on the capabilities of the model. The range of household types starts from 5 Nm. Semi-professional equipment has indicators of 15 Nm and higher, similar equipment for professionals can have an indicator of 60 - 140 Nm.

To work with rigid structures and metal, the tool will require more effort to unscrew or tighten the fasteners. Accordingly, his indicator should be higher. Also, when operating with a particular material, its physical properties should be taken into account. The higher the density, the greater the rotational force required.

The ratio of the indicator and the diameter of the fastener

Also, the determining value when purchasing equipment is the diameter of the fastening element. The following dependence can be seen here: the larger the part, the more effort should be made when working with it.

Selecting the Nm value for specific work

In order not to be unfounded, as an example we will give a table that shows the torque values when performing the operation of tightening a screw into a soft and hard base.

| Screw diameter (mm) | Value for soft material (Nm) | Value for solid material (Nm) |

| 6 | 10 | 25 |

| 7 | 11 | 27 |

| 8 | 14 | 30 |

Increasing the diameter of the screw requires greater force to be applied to the tightening tool. The value also increases accordingly when working with dense, hard materials. It must be remembered that the maximum value is formed when the start key of the tool is fully pressed.

Working with construction mixtures and solutions

A screwdriver is a universal tool. Builders and home craftsmen use it to prepare various mortars or mixtures.

Liquid solutions and mixtures will require little effort for mixing. For such work, you can use a simple household look. To mix heavier, viscous components, you will need a professional model or, in extreme cases, a semi-professional one with a high torque rating.

Using the above examples, the owner of the tool will be able to calculate, knowing its value, what length and diameter of screws the master can use for fastening.

For example, having a model with a torque of 15 Nm, its owner can use self-tapping screws 150 mm long to screw into wood. He can also select materials of the required density to complete his task.

How to choose a cordless drill/driver for your home. What types of screwdrivers are there?

This instrument is available in various modifications, which can be classified as follows:

- Cordless screwdriver. Designed only for working with fasteners such as screws, screws, self-tapping screws. Widely used on assembly lines.

- Impact wrench. Designed to work with bolts and nuts, used on assembly lines, car repair shops and other enterprises.

- Drill-driver. Designed for drilling, there is a low speed mode for tightening and unscrewing fasteners with a slot for a screwdriver.

- Screwdriver. Used for loosening and tightening fasteners with cross-shaped heads, as well as for drilling small-diameter holes in wood, plastic, non-ferrous metals and other soft materials.

To use a screwdriver you do not need any special skills. Even a small child can easily begin to twist and unscrew self-tapping screws if he is shown how to do it correctly. As soon as a drill-driver appears among household tools, the need for nails and a hammer immediately decreases. Battery-powered models are especially popular. They do not need an electrical network, so they are mobile, autonomous, and independent.

All screwdrivers are divided into two groups: professional and household. The main differences are price, tool capabilities and duration of continuous operation. Professional models are more durable, but not as functional; they have more powerful batteries that require charging much less often. The professional tool is made of durable materials, of high quality and is designed to work in “Spartan” conditions. It has a higher torque than a household tool, therefore it can drive screws into stronger and stronger materials.

Household screwdrivers are more versatile. They are more compact, lighter, and the rotation speed of the cartridge does not exceed 500 rpm.

When choosing an electric drill/driver for your home, take a closer look at household tools. Don't overpay for ultra-high reliability.

Types of screwdrivers

Screwdrivers are widely used in various fields:

- in construction;

- in interior decoration;

- in the production and installation of furniture, suspended ventilation systems, etc.;

- in the repair of cars and other equipment.

The stores offer a large selection of types and models of screwdrivers. Most often, such a tool is purchased to perform small household work, but there are also powerful professional systems that are highly reliable and cost significantly more.

All modern screwdrivers are divided into two groups depending on the power supply method:

- Battery-powered devices. Such units are heavy due to the battery. However, their important advantage should be considered mobility (this is an important quality for installation work).

- Devices operating from the electrical network. Such systems have great power, but can only be used near an outlet.

Cordless screwdriver

When choosing a tool, first of all, you should pay attention to the rotation speed. This characteristic will allow you to understand exactly how a particular model can be used.

How many Nm is needed to tighten a screw?

Before giving an exact answer, it is necessary to clarify which screw/screw and where. In the latter case, the density and hardness of the material matters. The table below will give you an idea of some approximate average density and hardness of individual types of wood at a humidity of 12-15%. In fact, the density of the same type of wood can vary over a relatively wide range, so some typical values are usually taken into account:

Read also: Flexible drill attachment

| Wood species | Density, g/cm 3 | Janka hardness |

| Siberian fir | 0,39 | 420 |

| Spruce | 0,45 | 660 |

| Aspen | 0,51 | 420 |

| Pine | 0,52 | 380-1240 |

| Linden | 0,53 | 400 |

| Birch | 0,65 | 1260 |

| Beech | 0,66 | 1300 |

| Larch | 0,66 | 1200 |

| Oak | 0,69 | 1360 |

| Yew | 0,75 | 1200 |

| Ash | 0,75 | 1320 |

| Plum | 0,8 |

1200

1200

This means that working with birch, for example, will require about twice as much force as working with spruce. However, the connection here is not entirely direct. More resinous wood will be easier to process.

Now let's move on to the screws. What matters to us is the diameter, length, shape and nature of the thread. For example, for thin screws when screwed into medium-hard wood (pine), we have the following picture:

| Apple tree | 0,9 | |

| Boxwood | 0,96 | 2100 |

| Screw dimensions, mm | Maximum torque, Nm |

| 4x50 | 3,56 |

| 4x90 | 4,92 |

| 5x50 | 5,36 |

| 5x90 | 7,24 |

Looking at the table, you might think that any of the commercially available screwdrivers will be suitable for 5x90 self-tapping screws. But this is not entirely true, as discussed in the practical part of the material.

- we do not know from what “ceiling” the figures for the torque characteristics of screwdrivers specified by the manufacturer are taken;

- Captain Obvious also suggests that the material used has a noticeable impact on the entire process, as well as the parameters of the screws.

How to choose a screwdriver - 9-step instructions

How to choose a screwdriver, 9-step instructions, an article from which you will learn everything about screwdrivers! Types, powers, characteristics, applications, comparisons.

We are preparing the orchestra for the working season. How to choose a screwdriver - 9-step instructions

To assemble furniture or hang a picture, today you don’t have to put in a lot of effort.

- The main thing is to choose the right tool!

This article will help you understand the variety of these tools and buy a screwdriver that is right for you.

Purpose of the tool

A screwdriver is only suitable for working with fasteners - an ideal assistant in assembling furniture or simple repair work.

There is also a universal tool: a drill-driver, which combines the first two functions - drilling and screwing.

Cordless screwdriver – performs the function of a screwdriver, and also allows you to unscrew and tighten fasteners. However, its power is lower than that of a conventional screwdriver.

Tool type

A classic of the genre is a hammerless drill or screwdriver. Such a tool makes only rotational movements. A hammerless drill is ideal for working with soft materials and wood.

- If you need to tighten screws or drill holes in the wall, this is a win-win option.

There are instruments with impact - in addition to rotational movements, they perform forward and backward movements. This allows you to drill into more durable materials: concrete, brick and various metals.

*Impact drills are more versatile - you can always turn off the impact function and switch to working with more fragile materials.

Angle tools are essential for working in confined spaces or hard-to-reach areas. Here the gearbox is shaped like the letter “L” and is fixed at an angle of 90 degrees – hence the name.

Some hammerless screwdrivers also have additional angle bits. For example, this is very convenient when working under the hood of a car.

Chuck type

Any screwdrivers are equipped with a chuck. This is the mechanism that holds the bit or drill bit. In screwdrivers, the cartridge is installed under the bits. A bit is a small attachment, hexagonal on one side and of various shapes on the other. To change the attachment, just remove one and insert the other until it clicks lightly.

Another important parameter is the diameter of the cartridge. It determines what size drill or bit can be used when working with the tool. For non-professional instruments, a sufficient range is from 0 to 20 mm.

Tool power

The power of the tool is determined by the voltage supplied by the battery. It varies from 1.2 to 36 volts.

Thus, for small jobs you can buy a screwdriver with a voltage of 3-6 volts. For drilling non-solid materials, a screwdriver with a voltage of 10-15 volts is suitable.

- When choosing a screwdriver, pay attention to the battery capacity - the operating time depends on it. The average is from 1 to 3 A/h.

Often included is a second battery for continuous operation, as well as a special charging base.

Maximum torque

Maximum torque – determines the effectiveness of the tool.

Based on this indicator, you can understand how large the diameter and length of the screw can be tightened by a screwdriver.

- Power, voltage and maximum torque are interrelated indicators. The higher the voltage, the higher the torque.

A screwdriver's maximum torque can be several N/m. This is quite enough to assemble a chair or bracket.

A screwdriver with a torque of 10-30 N/m - to cope with any task. Tighten the screw tightly in the metal shelving - no problem!

*A torque of 30-40 N/M will easily allow you to drill through wood.

A device with a maximum torque of 40 N/m and more - can easily cope with brick, concrete and metal surfaces

Number of speeds

As a rule, screwdrivers and screwdrivers have only one operating speed: from 0 to 800 rpm - this is enough to work with fasteners.

But most drills and screwdrivers have 2 speeds:

1st mode with speed from 0-400 rpm - mainly used for tightening.

2nd mode with speed from 400-1300 rpm - for drilling holes.

- Almost all screwdrivers are equipped with a “reverse” function for unscrewing fasteners.

additional information

When working with such tools, reliability and safety are important.

Many models have: locking the power button; battery protection system from overload, overheating and deep discharge; Illumination of the work area with a built-in LED flashlight.

When choosing a tool, pay attention to its weight - the higher the power of the screwdriver, the heavier it is.

Equipment

Screwdrivers usually come with a compact plastic or metal case and a battery charger, but sets of drills and attachments are most often purchased separately.

- Do not forget that when working with screwdrivers and drills, you must protect your eyes - use construction safety glasses.

Recipes

If you need a tool for simple work, a small and lightweight screwdriver with a voltage of 3 to 15 volts, with a built-in battery, with a quick-release chuck or a padded one will suit you.

For some types of work, it makes sense to buy an angle-type screwdriver - especially if you often repair your car.

If you use tools at home and occasionally: it’s worth buying a screwdriver-drill - hammerless or impact, with a voltage of 15 volts and a torque of 30 N/m, or better yet, with power support from the mains.

Are there major renovations ahead?

An impact drill with a voltage of 20 volts, with a quick-release or screw-in chuck for large drills, with a torque of 40 N/m and 2 speeds for different operating modes is ideal.

Each instrument has its own special sound! Do you have a whole orchestra?

How to choose a screwdriver - video

What is a Newton meter?

Again, to use a quote from Wikipedia, “one newton meter is equal to the moment of force created by a force equal to 1 N about a point located 1 m from the line of action of the force.”

Regarding the screwdriver, I will explain it as follows. The screwdriver chuck has an axis around which it rotates. Take a screwdriver and position its axis of rotation horizontally. Then we take an L-shaped metal rod, one of which has a length of 1 m, and the second (no matter what length) will be clamped in the chuck. So, if that side of the rod, which is equal to 1 m, is placed horizontally and a load weighing 100 g is suspended on its end opposite from the screwdriver, then we will obtain a torque acting on the cartridge approximately equal to one Newton meter. And if you hang, for example, a load of 4 kg, we get 40 Nm.

Therefore, if a screwdriver states, for example, that its maximum torque is 40 Nm, this means that the screwdriver engine through the gearbox transmits the same force to the chuck as if we had actually assembled the above structure and hung a 4 kg load. We will not take into account the mass of the rod itself.

That's what the torque of a screwdriver is.

Well, in conclusion, it must be said that the maximum torque is achieved when the start button is fully pressed. In addition, on two-speed screwdrivers, the torque will also be different at different speeds - more at the first, less at the second.

Screwdrivers also have a special regulator that has a scale with marks from 1 to 15, 20 or another number (as the manufacturer decides) and the last mark in the form of a drill (in this position you can and should drill), which limits the torque. That is, if you set the regulator to one of the numerical marks, then when a certain torque value is reached, the screwdriver no longer turns, but clicks. But if the regulator is set to the “drill” position, the screwdriver will not click, but will try to tighten what it is turning until the last minute. At the same time, the above numbers do not actually mean the moment itself, but simply show how much more or less you do it (just to quickly navigate when working)

I hope I was able to explain the essence of the torque of a screwdriver. With that, I’ll take my leave - see you next time!

Content:

Screwing in a screw is one of those tasks that seems to appear out of nowhere, but with enviable consistency. Fixing a lopsided closet door, hanging a mirror in the hallway, attaching a shelf in the bathroom are small everyday problems that need to be solved daily. It is possible to tighten a bolt, screw or self-tapping screw using a screwdriver, but it does not always work. Anyone who has tried it knows: it is a thankless, lengthy task, and the result is often zero. And it needs to be done quickly and efficiently.

Read also: com com cable wiring

Buying an electric screwdriver for everyday household work around the house is the best solution. Not to mention the fact that it is indispensable in the work of professionals. It is used on construction sites, during repairs and in furniture workshops. Using a screwdriver, they install plasterboard structures, install windows and doors, fasten baseboards and assemble furniture.

Choosing a screwdriver based solely on its cost is a grave mistake. They differ in power and various functions. In order not to make a mistake when choosing, you should carefully study its technical characteristics before purchasing. The main ones are rotation speed, torque and type of battery (in a cordless tool). But reading the digital data is half the battle; you also need to be able to figure out what indicators are needed specifically for you and for the planned work.