To choose the right equipment for welding, you need to know the design of the welding inverter and its operating principle. If you understand this well, then you can not only work with this tool, but also repair it yourself.

Today, there are quite a large number of inverter models available on the construction equipment market. This provides the opportunity to choose the most suitable tools, taking into account your own financial capabilities, with the functions required for the job. If you really want to save money, you can even make an inverter-type welding device with your own hands.

About the design

The inverter unit differs from the traditional welding transformer, which is familiar to every welder. The procedure for changing the type of current in the inverter is carried out differently; it consists of several stages, for which a mini-transformer is used, slightly larger than a pack of cigarettes. This type of tool is also distinguished by the presence of an electronic control system, which greatly simplifies welding work. Also, thanks to this system, the connecting seams are of higher quality. Most users of inverter welding leave extremely positive reviews, primarily due to the high-quality seam and compactness of the tool.

Electrical diagram

The welding inverter device includes the following components:

- The high-frequency pulse generator is an inverter unit, the design of which includes high-quality transistors.

- Rectifier for alternating current supplied from a standard electrical network.

- High frequency AC rectifier.

- A transformer that increases high-frequency current and decreases high-frequency voltage.

- Working shunt.

- Electronic control unit of the device.

- Starter charger.

Whatever properties a particular model of inverter device has, the operating principle is the same. It is based on the use of a high-frequency pulse converter.

Control block

The main advantage of an inverter device is the presence of an equipment control unit. Electronics are quite important during the operation of the device, since feedback occurs due to it. It allows you to fully control the electric arc, that is, maintain its necessary operating parameters.

Output rectifier

To produce a constant current at the output, high-quality output rectifiers are used for semi-automatic welding. This circuit is based on double diodes with a common cathode. Such components are characterized by increased operating speed; they instantly open and close. The response period of diodes of this type is about fifty nanoseconds. Speed matters in work.

Electronic system

Such a system with a charger from fifteen-volt voltage stabilizers, which are mounted on radiators. The main rectifier supplies the voltage. When applying voltage, which is currently rising, the capacitors must be charged first.

The diode assembly is protected by a limiting circuit equipped with a powerful resistor. After the capacitors are fully charged with the charger, welding will begin to work. The relay contacts close, and the resistor does not participate.

Additional items

- Control system, drivers. Here the main element is a PWM controller chip, which provides control of high-power transistors.

- Control and control circuits of various configurations. The main component in this case is a transformer, whose task is to control current parameters.

- Starting device from the welding unit.

- Voltage control unit, current parameters in the electrical network. This system includes an operational amplifier based on a microcircuit. The main purpose of the block is to launch emergency protection in an acute situation. The system also monitors the health of the electrical unit and monitors its operation.

Pros and cons of inverter welding

Inverter devices show efficiency in the range of 85 - 95%, I must say that this is a high figure among electronic equipment. The circuit used allows you to adjust the level of welding current from several amperes to hundreds, or even thousands.

For example, an inverter of the MMA brand, it is 20 - 220 A. Inverters can operate for a long time. The power supply can be controlled remotely. The undoubted advantages of inverters include their small size and weight characteristics, which allow the device to be moved at the welding site. The design of the devices uses double insulation, ensuring electrical safety.

Technological advantages

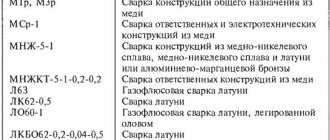

The use of inverters allows the use of electrodes of any brand that work with both direct and alternating current. Devices of this type can be used for welding with a non-consumable electrode in a shielding gas environment. In addition, the design of this equipment makes it easy to automate welding processes.

Tungsten electrodes for argon arc welding

Electrodes for resistance welding

Welding can be performed using a short arc, thus reducing energy losses and increasing the quality of the weld; in particular, there is virtually no welding spatter on the surface of the parts being welded. By the way, the use of inverters allows you to produce seams in any spatial configuration.

Microprocessor

Microprocessors are used to control modern welding inverters, and this ensures a stable connection between voltage and current.

Disadvantages of inverters

Inverters are somewhat more difficult to repair than traditional transformer units. If some control elements located on the board fail, repairs can cost about a third of the cost of a new welding inverter.

Inverters, unlike other types of equipment, are very susceptible to dust. That is, such devices must be serviced more often. Operation of an inverter welding machine is also limited by low temperatures. In addition, there are some restrictions on storing the inverter at sub-zero temperatures. This is fraught with the formation of condensation, which can lead to a short circuit on the board.

Operating principle of the device

The design of the inverter welding machine involves the operation of the equipment as follows:

- The alternating current of the electrical network changes with direct current. In this case, the voltage is 220V. The direct current supplied from the supply device is again changed by alternating current, but this time at high frequency.

- The high frequency AC voltage decreases. This significantly increases the current strength.

- The resulting high-frequency electric current with a lower voltage and greater strength is replaced by a constant current, on which welding work is carried out.

The main type of welding devices used earlier were transformer machines, which increased the welding current while decreasing the voltage. The main disadvantages of such instruments that are in use to this day are low efficiency (high energy costs for heating iron), significant weight, and dimensions of the equipment.

The invention of an inverter-type semi-automatic machine, in which the welding current is adjusted using a completely different technology, has made it possible to significantly reduce the weight of the unit and make it more compact. Thanks to the high frequency, effective current regulation is achieved. The higher the frequency, the smaller the device dimensions can be.

Rules for using the welding machine

Some people decide to hire a specialist to carry out the work, although in fact there is nothing difficult in working with such equipment. A semi-automatic welding machine or other modification requires compliance with certain rules before and during work. Before starting work:

- wear protective clothing and face protection;

- remove unnecessary items from the workplace;

- check the serviceability of the welding part of the apparatus;

- include the ventilation system.

During welding:

- lay the part stably;

- the flame can only be viewed through protection;

- electrode cinders are thrown into a special box;

- during short breaks, the electrode holder is hung on a stand;

- If there is carbon deposits on the electrode, clean it by first turning off the transformer.

Let's sum it up

Thanks to the above characteristics, inverter units are in great demand today among professional welders. With a compact, lightweight tool it is much more comfortable to carry out various types of installation work. The device, which weighs only about five kilograms, can be hung over your shoulder and safely carry out welding work while standing on a ladder.

This universal equipment is perfect for young welders who do not yet have sufficient experience, since easy ignition and combustion stability are ensured by the electronic control system with which the inverters are equipped. According to these criteria, even high-quality transformers cannot be compared.

Determining the characteristics

Like any technical equipment, welding inverters have a number of technical parameters that determine their capabilities.

Welding current

Inverter welding machines provide the generation of welding current in the range from 100 to 250 A.

Open circuit voltage

After converting the current supplied from the electrical network to 220 V, a current with a voltage of 50 - 90 V and an operating frequency of 20 - 50 kHz is obtained at the output of the device. Maximum voltage must be used to ignite the arc, but this creates a safety hazard for the welder and surrounding people. Therefore, after finishing work, the voltage drops to a safe level.

Maximum current operating mode

An important indicator of the operation of any welding machine is the operating time. It may be called PN or PV. This indicator indicates how long the device will operate with a ten-minute welding cycle before shutting down.

In other words, if the duty cycle is 50%, this means that the effective operating time will be 5 minutes, if the indicator is 70%, then the time will be 7 minutes. This indicator must be reflected in the technical documentation included in the delivery of the welding machine.

Differences from transformer welding equipment

The operating principle of the welding machine is based on the power parameters of the power transformer - the main structural element. In an induction coil, there is a relationship between voltage and current: the higher the strength, the lower the voltage characteristics. This change allows welding work to be carried out.

The inverter differs in that the circuit has the ability to obtain high-frequency current through double conversion of the electric flow. The process allows you to install a light weight transformer. A standard welding unit with a coil weighing 21 kg supplies a current of 160 amperes to the electrode; when using an inverter, a similar power indicator is generated when installing a transformer weighing 400 g.

Welding metal - some important features

If you have already learned how to lay a welding seam, then you can move on to more complex actions. Connecting two parts by welding has some features that are important to know for a beginner trying to learn how to use welding. These are the following features:

- When connecting two parts, it is necessary to take into account that they may become distorted. This happens due to the fact that when the seam is pulled, the part is mixed

- To prevent distortion of the parts being connected, you will need to secure them first. This is done in different ways - fastening with clamps and other ties, as well as by welding tacks

- Tack welding is the most common method of welding two parts together. It is done like this - first you need to attach the parts to each other, and connect them in this position by point connection. Next, weld the parts together using a welding seam

Having mastered the technology of using a welding machine, you can move on to performing more complex manipulations. When welding, it is important to follow safety precautions to avoid the possibility of injury.

To summarize, it should be noted that learning to use welding at home is not difficult. To do this, it is recommended to select the appropriate device and prepare for training. Having a welding machine at your disposal, all that remains is to learn how to use it.

How the electrode moves during welding

Having understood the question of how to light a welding arc, as well as the peculiarities of holding the electrode, you can get down to business. When the arc is lit, you need to keep the electrode at a distance of 2-3 mm from the outer part of the workpiece. This is where all the skill of the welder comes into play. To gain welding skills, you need to practice holding a lit electrode. The whole difficulty when moving the electrode is that the following must be taken into account:

- The trajectory of the electrode movement must be pre-selected. Electrode movement options are presented below

- When working with the device, you need to know that the length of the electrode decreases as it moves. To prevent the arc from disappearing, you need to maintain a constant distance of 2-3 mm

- The size of the weld pool is adjusted by increasing or decreasing the speed of movement of the electrode. The lower the speed, the larger the seam size

- Pay attention to the direction of the seam, since work must be carried out exclusively with specialized safety glasses or a mask.

Learning to work with electric welding is not difficult, but before moving on to serious manipulations, you need to gain experience. To learn how to “lay” even seams, you should first draw a line with chalk and then navigate along it. This will eliminate the need to control the evenness of the seam at the initial stage of training.

This is interesting!

Take your time to weld the two parts. First you need to learn how to lay even seams, and only after that try to connect two parts.