It is very difficult to manage on a private plot or cottage without a hand hacksaw for wood. This tool is also called a hacksaw. With such a simple device you can cut down trees or branches in the garden, shorten fences and perform many other types of work where you need to change the length of some wooden product: boards, laminate, and so on.

It’s unlikely that anyone has seriously thought about this, but if you make the right choice of saw, its service life, as well as ease of use and cut quality will depend on this. That is why it is necessary to know all the basic parameters for the correct selection of such carpentry tools.

Tape

The band saw is a continuation of the jigsaw. Its canvas is represented by a belt with teeth, which is closed and driven by an electric motor. Compared to a jigsaw, it provides greater precision and cleanliness of the cut. The cutting depth can be 8-50 cm. Neither a circular saw nor a jigsaw can achieve the maximum cutting depth with a band saw.

- According to the material of manufacture. carbon and alloy saws. The latter are characterized by increased wear resistance.

- According to the manufacturing technology and hardening of the teeth, the tapes are classified into saw blades with cut unhardened teeth and cut hardened teeth.

The first saws are inexpensive and allow you to cut wood that has various inclusions. It is logical that low speeds and small amounts of work are used here. Second saws have a high cost, but also high wear resistance.

For shape cutting, 3/8-inch blades are used, for ordinary woodworking. 1/2 inch.

TOP—7. The best hand hacksaws for the garden and workshop (for wood, metal, with large teeth).

There are also band saws for cutting metal, similar in design to a woodworking band saw, but allowing only cross-cutting of rolled steel. This cut can be made at various angles.

Hand saw for wood - secrets of selection and use

Currently, both in home workshops and in production workshops, various tools are widely used for cutting wooden beams and boards, cutting slabs, which are also based on wood processing products. These are hand-held circular, band and reciprocating saws for wood. All of them are electric, that is, their working part is driven by an electric motor of the required power.

With all the undeniable advantages of electric hand saws for wood, they also have a number of negative features:

- dependence on energy sources;

- low degree of mobility;

- demands on the experience of the employee using them;

- high cost of both the tool itself and its consumable parts, associated repairs and additional equipment.

Very often the amount of woodwork is small or this work is performed extremely rarely. And buying for them, for example, a hand-held electric circular saw for wood, is an expensive undertaking.

- The use of hand tools resolves all contradictions and allows you to overcome the disadvantages of mechanized woodworking tools.

Of course, you can buy a very cheap power tool, but then there is a threat to the safety of the worker himself and the guarantee of receiving a high-quality product completely disappears. It seems that this situation is hopeless, but it is not.

The way out that resolves all the contradictions and allows you to overcome the disadvantages of mechanized woodworking tools is to use hand tools. First of all, this is a hand saw for wood.

Characteristics of hand saws

Longitudinal cutting is intended for cutting wood along the grain. The teeth of these saws are sharpened on both sides, so they cut equally forward and backward. Cross cutting is designed for cutting wood across the grain. Their sharpening is similar to rip saws, so cutting is carried out both forward and backward.

The following types of saw teeth are distinguished: small, medium and large, they are marked according to the TPI standard. The finer the teeth, the better the quality of the cut they provide.

Wood saws can be cross-cut, rip-cut or universal. Today on the market you can find saws with gaps between the teeth. This type of hand saw is designed for cutting raw wood.

The hacksaw is designed for making rough cuts. If you use a miter box, you can use it to make cuts at a certain angle.

Selection by purpose

As we have already found out, there is a wide variety of saws, but the choice of a hacksaw should also be carried out in accordance with certain types of work:

- For rip cutting you must use a swing saw.

- The transverse one will cope well with wood where there is a transverse arrangement of fibers.

- The tenon tool can be used to cut various grooves and tenons, as well as technological recesses in the wood.

- The round cutter cuts out holes of various shapes.

- A folding hacksaw is used on trees.

The choice should always be made according to the main purpose for which a certain tool is purchased. A saw with replaceable blades is suitable for household use, and it is also advisable to have several types of cutting tools at home.

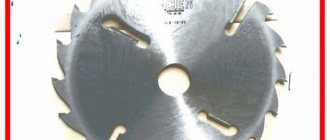

Disk

Here, the reciprocating movements of hand saws are replaced by circular ones, mainly due to the use not of manual force, but of the power of an electric motor.

The following types of circular saws are distinguished by design: geared (the motor operates due to a gearbox on the shaft of which there is a disk) and gearless (the disk is fixed to the motor rotor shaft).

Geared saws are characterized by deep cuts compared to gearless ones. In the latter, the disk may have teeth having a direction coinciding with the direction of movement. In this case, the disk is called active. Otherwise, it is called passive (inclination of the teeth against the direction of movement). The first discs are used for sawing wood, the second. metal

A small number of manufacturers produce hand-held circular saws that can be mounted upside down on a table and used as circular saws.

Some circular saws have a handle for comfortable operation, while some are table-mounted and do not have a handle. The fixed part can rotate up to 60 o. This allows these saws to be used in the manufacture of slats, linings, and plinths.

Circular saws should come with rulers to ensure the most accurate cutting.

An electric circular saw allows you to prepare tenons and remove quarters from wood products.

Electrical

These types of saws are characterized by quiet operation, lightness, absence of gases (unlike chainsaws), and the ability to start in any room if electricity is available. These are their positive qualities, but there are also negative ones. These include, first of all, the need for an electrical network, which is not typical for absolutely any conditions. In addition, these saws can be used at a certain voltage level and their service life is limited to 5 years.

The following types of electric saws are distinguished: circular, circulating, miter saws (characteristics are given below), chain, reciprocating, and electric hacksaw.

Electric chain saws can be used in the garden, preparing firewood. They are longitudinal and transverse.

The reciprocating saw fits tightly to the material being cut. She performs carpentry, joinery and roofing work.

The blade of an electric hacksaw moves along two guides. It is characterized by good safety and cutting accuracy.

Carbide-tipped discs are used for working with hard wood, plastic, and thin metal.

Circulating

These types of saws are used for sawing fairly hard materials such as wood or plastic.

For different types of circular saws, you can change the cutting angle and depth. They can be used to make longitudinal, transverse, and inclined cuts.

The more teeth there are on the disk, the better the quality of the cut. However, these disks reduce the performance of circular machines. Therefore, carbide-tipped discs are now used.

Compared to a jigsaw, circular saws provide greater precision but are heavier.

Types of circular saws are distinguished depending on the blades used. Thus, carbide-tipped discs are used when it is necessary to cut hard wood, nails, thin metal, and plastic. When using discs without soldering, clean (unlike the previous type) and even cuts are obtained, however, such discs are intended only for soft wood.

Stationary circular saws can be with a closed cast base, lightweight or hybrid. Lightweight circular saws are mainly used at home. The bed can be made of steel and cast iron, but is always open, unlike professional models. It also uses a lightweight suspension. Professional models allow you to make cuts up to 250 mm, and lightweight ones. up to 90 mm. The vibration of the latter types is much higher, power is supplied from a 220 V network, while in professional ones. mainly from 380 V.

Hybrid circulation saws have a closed frame, are low in cost and operate on household power. The maximum workpiece depth for the main models of saws does not exceed 75 cm. Hybrid and lightweight circular saws have a power of up to 2 kW, and professional ones. above this value.

READ Stihl Chainsaw Won't Lube

Boning saw

At first glance, such a saw looks like a hacksaw and consists of a cutting blade and a handle. Such a device has a backing that is applied to the upper part of the metal sheet, giving the product rigidity. This is necessary so that the canvas performs its function smoothly and without hesitation. The blade of this tool has hardened teeth, which allows for precise cutting.

Features of Japanese technology of axing saws.

- The saw handle can be larger in size than the blade itself. It resembles the handle of a sword.

- Thin blade blade: up to one millimeter.

- The cut is made by moving towards you.

According to their shape and purpose, Japanese saws are divided into several types.

- Universal - they have a wide blade, their cutting teeth are located on both sides of the blade.

- To ensure product strength and limit the depth of cut, rectangular blades without limiters are used.

- Tools for long cuts.

- To remove knots and protrusions on wood, use products with a thin blade.

- Equipment for making wooden figurines.

- Devices for processing wooden products in hard-to-reach places.

Saws with gasoline engines from Japanese manufacturers are easy to operate and have fairly clear technical equipment. Such goods are sold at affordable prices even in the Russian Federation.

Japanese technologies for the production of gasoline saws are recognized throughout the world. Manufacturers take into account characteristics that are important for the efficiency of saw engines, such as mixture formation, compression ratios and channel shapes. Thus, their engines have a large power reserve, but at the same time the mass of the tool as a whole is preserved and gasoline consumption is reduced.

In addition, saws from Japan are distinguished by their environmental friendliness, safety and silent operation.

But a rather significant disadvantage of Japanese chainsaws is the high price not so much of the tools themselves, but of the components and maintenance.

The main advantages include:

- Long service life of the product even under high loads and in harsh climatic conditions.

- Compact weight, gas saving and high performance.

- Affordable price compared to European analogues.

- The equipment has a multi-stage cleaning system. It minimizes the release of toxins into the environment.

- Modern design that attracts the eye. It's nice to have such equipment in your arsenal of home appliances.

- A high-quality approach to the production of products, both economical options and professional saws.

Vivid examples of Japanese-made chainsaws include products from Echo. The saws of the presented company are enviably popular.

The most popular are the following models.

- Echo 350. The engine has a built-in pump that pumps fuel, and there is also a device for easy starting of the unit. The main difference from other similar equipment is the harmonious combination of weight, power and production technology. The large engine capacity is one of the advantages over competitors.

- Echo 3500. A small but quite powerful chainsaw. It differs from its competitors in its reliability and stability. Easy to use and does not require professional skills to operate.

- Echo 353. This model is most often used by farmers. High quality, environmental friendliness, and simple operation of the unit provide an excellent opportunity to use it in everyday life, ahead of competitors.

Classification of hand saws

Hand saws with rip or cross cuts are called hacksaws. They are divided into tools for metal and wood.

The following types of hand saws are distinguished by purpose:

- classic. with longitudinal or transverse cut,

- thorny. used for cutting connecting tenons,

- rounded. used for cutting holes.

Hand saws are classified according to blade size:

- for mini-hacksaws (with a blade length of up to 350 mm, with frequent small teeth, mainly intended for carpentry work);

- universal (blade length up to 550 mm, medium teeth, intended for both joinery and carpentry work);

- wide (blade length more than 600 mm, large teeth, used for carpentry work).

In addition to hacksaws, types of saws for hand use include:

- Bow saws, which are designed for making point cuts because their blade is thin and flexible. If large cuts are made with hacksaws, then with bow saws. small.

- Circular, designed for making cuts in any direction, chamfering, making workpieces, making cuts.

Circular saws are characterized by the presence of a long, narrow blade.

Tenon saws (tenon saws) are similar to a plane with two handles. Designed for cutting tenons and grooves.

Hand saws also include back saws (with a rectangular blade limited at the top by a blade that limits the cut by the width of the blade, the handle is located at an angle of 45°), folding saws (with a folding blade and fine teeth) and garden saws (a blade in the form of a saber, used for pruning trees in garden).

For the purpose of metal processing, only one type of hacksaw is used with blades of different widths and fine teeth. The blade is fixed in the bow holder and secured with a screw.

Basic parameters of hand tools for cutting wood

A hacksaw is one of the most necessary tools in every man's inventory. This device allows you to easily change the dimensions of wood and plastic lumber. Using a hacksaw, you can perform a lot of operations in construction, cut branches in the garden, shorten fence poles, and so on.

A hand saw is used to work with lumber

But when purchasing such a seemingly simple tool, not everyone thinks about how to make the right choice and what criteria need to be taken into account. A hacksaw has its own special parameters that can affect the quality of work. There are four basic parameters when choosing a hacksaw: blade length, tooth size, steel type and handle type.

Jigsaw

A jigsaw, much like a coping saw, has a long, thin blade used for making intricate cuts. The jigsaw has a longer, larger frame that allows you to cut further from the outer edges, but the blade cannot rotate, resulting in a more tedious and difficult experience when making complex cuts.

Mixed hacksaws allow you to cut not only along and across the fibers, but also at an angle.

The shape of the teeth differs for different types of sawing

Handle type

The ease of use of the saw depends on the correct choice of saw handle. Handles are made of wood or plastic. A very important point is that the surface at the grip site should be such that the hand does not slip. This can be eliminated by scarring the handle or covering it with a rubber layer. The hacksaw can be either a classic cast saw or with a reversible blade. The latter allows you to replace the canvas, which is very convenient.

Types of hacksaws

Hand saws come in two configurations – wood and metal. Wood saws have large teeth and can also be used for cutting aerated concrete and drywall. Metal saws are capable of cutting almost any material, including wood, plastic, drywall, aerated concrete, polystyrene foam, polystyrene foam, etc. They have small cutters, so the cut is neat, and small chips are formed.

But modern hacksaws, unlike classic ones, have hardened teeth with a non-standard trapezoidal shape. Such saws are endowed with increased strength and are resistant to wear. Their steel cannot be sharpened, and it is very difficult to maintain all the angles of the sharpened teeth.

Modern hacksaws are made with hardened teeth in the shape of a trapezoid.

How to sharpen a hacksaw?

After carrying out a certain amount of work with a hacksaw, the saw teeth simply become dull. The first signs of the need for sharpening include:

- Heavy and uneven cutting.

- Uneven cut.

- The blade often gets stuck.

- It is difficult to maintain a given trajectory.

When the above “symptoms” appear, every master should understand how to sharpen a hacksaw while maintaining the working profile of the teeth:

- Securely fix the tool in a vice or clamp.

- Set the teeth. This procedure involves alternately bending each tooth in different directions by the same amount, approximately 1.5-2 mm, with a special tool.

- A triangular file with a fine notch is selected.

- The sharpening angle of the teeth is determined by eye, which is approximately 15-30º.

- Carry out the same number of file movements in the selected direction on one side. Repeat the process for the other side.

- The teeth are aligned in height.

Unusual hiking hacksaws

A hacksaw is not only a metalworking and carpentry tool, but also an effective tool for preparing firewood. It makes it much easier to split a tree trunk into blocks than using an axe. In this regard, there are specialized camping saws that are compact in size. Their main task is to provide an easy cross cut. The vast majority of these models fold like a regular pocket knife.

There are also universal pocket hacksaws, the design of which involves folding the working blade inside the handle, as is the case with a mounting or stationery knife. This tool is designed for working with wood and scrap metal. It is convenient to carry with you, but the effectiveness of use is minimal and will allow you to perform simple tasks.

A compact metal file, which is a small handle that fits onto the blade, is very convenient to carry. Such a weapon is as compact and inexpensive as possible. During operation, there is a high probability of breaking the canvas, since it constantly bends.

What it is?

An axing saw is a carpentry tool for cutting wood. It will help create a thin and precise cut. The main feature and difference from other types of hand saws in this case is the presence of a backing. Since the saw has a thin blade with fine teeth that can easily break, it is necessary to give it additional rigidity. This is exactly the function that the butt performs. The casing is made of steel or brass.

Any saw bends during operation, as a result of which the sawing speed decreases. In conventional hacksaws, the tendency to bend is reduced by increasing the rigidity of the blade, namely increasing its thickness. However, as the thickness increases, the thickness of the cut also increases.

Among the disadvantages of such a saw, one can note the fact that the butt does not allow cutting deeper than the width of the blade.

Most often, such a saw has teeth in the form of a right triangle. In order to cut down the spikes, you should use a hacksaw with a curved handle.

Jigsaw

Circular saws and chain saws cannot replace a device that uses a narrow cutting blade that moves up and down at high frequency.

Thanks to this arrangement of the working body, the jigsaw allows you to quickly and accurately cut curved flat parts. Plywood, ceramics and plastic, OSB and soft metal - all of this can be cut with a good jigsaw with a quality file.

For each material, manufacturers make special saws that differ both in the inclination of the teeth and in their frequency.

READ How to Cut Porcelain Tile with a Manual Tile Cutter

For example, a saw with a large tooth cuts wood better. A blade with a fine toothed notch can handle sheet metal with confidence. We will not give any special recommendations on choosing saws for a jigsaw, since the manufacturer indicates the recommended type of material on each of them.

The main technical parameters of a jigsaw are engine power, saw speed and maximum cutting depth (indicated for different materials).

For household models, these parameters are within the following limits:

- Power from 400 to 900 W;

- Speed (with the possibility of smooth adjustment from 0 to 3000 rpm);

- Cutting depth (wood - 45-80 mm, steel from 4 to 20 mm).

A useful jigsaw option is a laser pointer. It helps you clearly see the direction of the cut when the marking line is hidden under a layer of sawdust. When choosing an electric jigsaw, pay special attention to the attachment in which the file is attached. It should provide the most reliable clamping possible. Otherwise, the file will regularly jump out of its weak “embrace.”

Circular saws

The idea of replacing the back-and-forth motion of the cutting blade with a circular one can rightfully be called revolutionary. It arose after the advent of the electric motor and significantly increased the speed and productivity of work.

A typical tool that uses this principle is a circular saw. Its main advantages - mobility and high power - have overshadowed the modest capabilities of a hand hacksaw.

By design, circular electric saws are divided into geared and gearless. In the first case, the electric motor rotates a gear reducer, on the shaft of which there is a saw blade. The second option is to mount the disk directly on the rotor shaft of the electric motor. Both designs have a mechanism for adjusting the cutting depth and tilt angle.

The advantage of gear mechanisms is the ability to make deeper cuts. Gearless saws have two advantages: lighter weight and affordable price.

The second category of differences consists in the features of the saw blade. It can be active or passive. Everything here is determined by the shape of the tooth. The active disk has teeth bent in the direction of rotation.

In the passive one, they are tilted against the stroke (negative sharpening angle).

Passive discs are indispensable when sawing metal. Active ones are used for wood processing. The teeth of the disc can be tipped with carbide. They make it possible to cut harder materials, but have a negative effect on the cleanliness of the cut.

The operating capabilities of the tool depend on the power of the electric motor (from 0.65 to 2.5 kW). Manufacturers also indicate the maximum depth of cut that can be made using a circular saw (from 25 to 85 mm).

A variation of this power tool is a circular saw, which is mounted on a stationary frame. This solution allows you to cut long and wide materials with high precision.

Some manufacturers offer an interesting compromise - hand-held circular saws that can be turned over and mounted on a table, turning them into a stationary “circular saw”.

When answering the question of what types of saws there are, one cannot fail to mention cross-cutting devices. In this case, the circular saw is mounted on a pendulum arm. A rotating plate with transporter (angular) markings is used as a bed.

The advantages of a miter saw over a circular saw are obvious: you can make perfectly precise cross cuts at any angle. This operation is especially important when joining various wooden parts (platband, plinth, lining, timber).

Saw blade

Japanese models are distinguished by their diversity: manual, gasoline and electric. Another important detail when choosing a saw is the blade. It affects work productivity and quality cutting. Such equipment has a narrow focus and is made from specific special materials.

Each manufacturer himself chooses the type suitable for production from the classification of canvases: some according to the material, and some according to the scope of application of the tool.

Chainsaws

Often when working with wood, it is not the cleanliness and accuracy of the cut that is important, but its depth. This is exactly the problem that a chain saw solves - a powerful device with an electric or gasoline motor, designed for felling forests and cutting firewood.

It has two main interrelated technical parameters:

- Engine power;

- Tire length.

A bar is two flat plates connected to each other with a small gap for installing a saw chain. At one end it has a driven sprocket, and at the other there are cutouts for the tensioning mechanism.

The power of electric chain saws ranges from 1.5 to 4 kW. When choosing a device for household work on the site, it is better to choose a power of 1.5 to 2 kW with a saw bar length of 30 to 40 cm. This is quite enough not only for sanitary pruning of the garden, but also for preparing firewood.

If necessary, you can use this tool to dismantle a board, log or beam, although you will not get high quality and precision cutting.

There are two subtypes of electric chain saws:

- With lateral (transverse) engine placement;

- With longitudinal installation of the motor.

The first type is simpler in design and cheaper in price. But the second one is more convenient to use, although it is more expensive due to the introduction of a gearbox into the design.

The main thing that a chainsaw gives its owner is autonomy. With such a tool you can go into the forest and cut wood there. For such a significant advantage you will have to pay a price: chainsaws are more complex in design than electric ones. This difference is especially noticeable when purchasing a cheap “no-hire” device. Problems with starting, carburetor, rings and spark plugs are frequent companions of such a purchase. Therefore, it is better to purchase a more expensive chainsaw than to lose money when using an economy option.

Types of saws

Type 1: Classic

This type is the most common and is found in both amateur and professional workshops. The blade length of this saw can vary around 50-60 cm . Often these saws are equipped with a quick blade change mechanism and can be used quite easily for a variety of jobs.

Often these saws are preferred by amateurs. The disadvantage of these saws may be the low quality of workmanship - the blade may not be firmly fixed. This reduces the accuracy of cutting workpieces. But an undeniable advantage is the fairly affordable price of this instrument.

Type 2: Narrow

It's a circular hacksaw. The blade is of medium length, pointed at the end and non-replaceable. This is a manual alternative to an electric jigsaw. It is convenient to perform complex profile cuts in sheet materials such as plywood, fiberboard, chipboard and the like. There is a version of this saw for working on drywall.

Type 3: With pad

She's an abrasive saw. It is called so because of the thickening along the upper edge of the canvas, the so-called hem. It is made from a thick sheet of metal. Its main function is to provide rigidity when sawing. This makes the cuts very precise, but limits their depth. Often a saw is used in tandem with a miter box.

- A miter box is a “U”-shaped device with six cuts. It is made of wood, light alloys or plastic. The miter box allows you to quickly and accurately cut workpieces at a predetermined angle. Usually it is 45 or 90 degrees .

Type 4: Bow

In its simple execution it lives up to its name. It looks like a bow with a thin and long saw blade instead of a string. The frame of this saw can be made of wood or metal. Often a bow saw is equipped with a blade tension device.

In general, this type of saw is a manual analogue of a band saw or, in some cases, a circular saw. It is worth using onion in cases of one-time, sporadic use. That is, when buying an expensive band saw machine is not economically justified.

It all started with a simple hacksaw

It is this saw that is the ancestor of the family of hand tools designed for wood processing. As soon as the first ingot of iron was smelted, a person had the idea to forge a tool from it for cultivating the earth.

It can be assumed that the ax became second after the hoe. The third was probably a saw with a handle, known to us today as a hacksaw. Over the centuries since its invention, it has acquired numerous “brothers and sisters” performing dozens of different jobs.

The accepted classification divides this type of hand saws into two groups:

- Wood saws;

- Hacksaws for metal.

Depending on the direction of cutting, hand saws for wood are divided into three categories:

- For rip sawing cutting;

- For cross cutting;

- Universal (longitudinal-transverse).

The difference between them is in the shape of the cutting teeth: on a rip saw they are inclined forward, while on a cross saw they are straight.

The universal hacksaw tooth is also inclined forward, but has a special sharpening. It allows you to cut along and across the fibers.

According to their purpose, hand saws are divided into several types:

- Classic hacksaws (transverse or longitudinal cutting);

- Circular saws (for cutting holes);

- Tenon saws (for cutting connecting tenons).

When choosing a hand hacksaw, not only the shape but the size of the teeth plays an important role.

There are three types of incisors:

- Fine tooth – 2.0-2.5 mm (for high-precision sawing and cutting small products);

- Average tooth – 3.0-3.5 mm (for medium-sized parts);

- Large tooth – 4.0-6.0 mm (for rough cutting of timber and logs).

READ Chainsaw Attachment Drill For Earthworks

The international classification divides hacksaws not by the height of the teeth, but by their number per 1 inch of cutting blade. This standard has taken root here too, so don’t be surprised if you see the letters PPI or TPI on the instrument label. The number behind them is the number of teeth per inch of length. The larger it is, the finer the tooth (for example, PPI 8 or TPI 14).

Today you can see a modernized type of hacksaws on the market. They are easily distinguished by the gaps cut into the canvas. As a result, the teeth are arranged in groups of 6-7 pieces.

This tool is designed for cutting raw wood. The spaces between the teeth are needed so that wet chips do not clog the cut and can be easily removed during work.

Types of hand saws for the workshop. Profiles and tooth sharpening. DIY educational program

In addition to the usual hand hacksaws, users today are offered an electrified version of the tool. A powerful electric hacksaw can easily cope with a large volume of work on cutting lumber without tiring the owner too much.

Its versatility is achieved by being equipped with saws with different lengths and widths of blades and tooth sizes. This allows you to successfully work not only on wood, but also on plastic and metal. Another name for this tool is a reciprocating saw.

The main parameter characterizing the capabilities of electric hacksaws is power. It ranges from 400 to 1600 W. The cutting depth directly depends on it, which ranges from 90 mm for household models to 200 mm for professional models.

Hand tools for metal working are not so diverse. There is only one type of hand saw that can cut this material. Its working body is a wide or narrow blade with small hardened teeth. It is inserted into the bow holder and tightened with a screw.

Video description

Video on how to choose the right hacksaw for wood:

- Stanley Jetcut 2-15-283. This hand saw model was included in the rating of hacksaws for wood as the best among universal ones. Thanks to the 3-sided sharpening of the teeth and a fairly long blade - 45 cm - the tool allows you to saw almost any workpiece without clamping. Disadvantage: the cut is not of very high quality and is not suitable for processing finishing parts.

- BAHCO LAPLANDER 396-LAP. Folding universal saw. Application – construction, tourism, hunting, fishing, gardening. The universal shape of the teeth allows you to cut wood both lengthwise and crosswise. Canvas length 23 cm.

Note! When choosing a saw, it matters how often it will be used. For periodic use, a model with hardened teeth is suitable; for frequent use, it is better to use one made of standard steel, since inevitable grinding will require constant updating of the cutting part, which cannot be done with an analogue made of hardened material.

Band-saw

The logical development of the jigsaw design was the compact band saw. Its working body is a closed steel belt with teeth, which is rotated by an electric motor.

Sawing with it is easier than working with a jigsaw, which vibrates strongly and tends to break out of your hands. The cleanliness and precision of the cut of a band saw is ideal. This not only reduces waste, but also produces a cut surface that does not require sanding.

Here the workpiece can be held with both hands, which increases the accuracy of operations when cutting curved elements.

The main indicator of band saws for wood is the cutting depth, which can range from 8 to 50 cm. A jigsaw and a circular saw are not capable of cutting such thick material.

The remaining characteristics relate to cutting blades.

There are two categories here:

- Carbon saws (manufactured steel C75 and analogues);

- Alloy saws made of D6A steel (have increased wear resistance and resistance to alternating loads).

Depending on the manufacturing technology and hardening of cutting teeth, blades are divided into two types:

- Saw blades with a notched, unhardened tooth;

- Blades with cut hardened teeth.

The advantages of saws of the first type are low cost and the ability to cut wood with foreign inclusions: nails, stones, splinters. This blade is used for small sawing volumes (2-4 m3 per day) and at a minimum feed speed (6-10 meters per minute).

The main advantage of a saw blade with a hardened tooth is its high wear resistance (2 times higher than that of saws with non-hardened cutters). Disadvantages - high cost and sensitivity to foreign inclusions.

The remaining parameters of band saws are summarized in a simple list:

- Web width;

- Number of teeth per inch of length (TPI).

For standard wood sawing jobs, a 1/2″ wide strip is ideal. Narrower blades (3/8") are used for shape cutting.

The number of teeth of the cutting band directly affects the evenness of the cut (the more teeth there are, the smoother the cut). Coarse saw blades (2.3 TPI) are used for cutting wood and logs up to 200 mm thick. For cleaner work, saws with 6 TPI are used, and for precise cutting, a size of 10-14 TPI is used. The optimal size at which high productivity and good cutting quality are achieved is 8 TPI.

A table saw for metal is similar in design to a device for cutting wood. However, its capabilities are more modest. This tool can only perform cross cutting of rolled steel (pipes, angles, fittings, channels) at different angles.

How to choose a saw

The specific type of saw is chosen depending on the tasks to be performed. You need to pay attention to the following characteristics that any hand saw for wood has:

- size and shape of teeth;

- steel type;

- saw blade length;

- shape and material of the handle.

1. Size, number and shape of teeth. In short, all types of teeth that a hand saw for wood can have are combined into three groups:

- for longitudinal sawing, that is, along wood fibers. The shape is beveled triangles, sharpened on both sides.;

- for transverse - across the fibers. The teeth in this case are equilateral triangles;

- universal - for them the direction of the fibers does not matter. Here the teeth of the first two types are combined. In addition to this, they are collected in small groups, separated by special recesses.

For modern saws, there is a special TPI indicator, which is reflected in the tool’s passport, and means the number and size of teeth on one inch of the saw blade. The higher the indicator, the more accurate the cut such a tool gives.

- The accuracy of work is inversely related to the speed and effort expended. This must be taken into account in advance when starting work and choosing a tool. For example, if long-term work is expected, you should give preference to a tool with a more comfortable handle equipped with high-quality damping rubber inserts. This will protect you from calluses on your palms and from overloading the ligaments of your hand and wrist.

The shape of the teeth is as follows:

- "Wolf's tooth" - used for sawing raw wood.

- “Jet-cut” is the name given to the combination of six set dagger-shaped teeth with two of the same undrawn ones.

- "Japanese tooth" - used in Japanese hand saws for wood. It is distinguished by its reverse wedge shape and, as a result, the wiring is unnecessary.

- “Simple dagger tooth” - has the shape of an equilateral triangle (this allows you to saw in countermovement), the setting is done every other third of the thickness of the blade. Saws with such teeth are intended exclusively for sawing wood across the grain. This tooth is widely found on hacksaw and bow saw blades.

- “Tooth-chisel” - so called because its top is sharpened transversely relative to the blade. The shape is a beveled right triangle. This tooth is used exclusively for cross-cutting wood with hacksaws and axle saws.

- “Universal tooth” is a synthesis of simple dagger and chisel teeth. Has a sharpened leading edge. Because of this, a saw with such teeth is universal in relation to wood fibers. This type of tooth is used in all circular saws.

2. Type of steel. Most often, hand saws are made from low carbon steel. This makes the fabric quite flexible and elastic at the same time. You can sharpen the teeth on such saws yourself. Stainless steel saws are the most durable.

Of course, you need to remember that stainless steel can also be destroyed by rust if storage and operating conditions are violated. Recently, saws with hardened teeth have become popular among home craftsmen.

For sporadic work, this is a beneficial solution, as they hold an edge well. But they have a significant drawback - after grinding, the teeth cannot be restored at home. In fact, such a saw is disposable.

3. Saw blade length. According to this parameter, all saws are divided into three groups:

- mini - their length is no more than 35 cm.

- universal - length from 36 to 55 cm .

- wide (large) - the length of the canvas is more than 56 cm.

4. Shape and material of the handle . They are quite varied and depend on the type of work performed. They can be quite minimalistic (like, for example, Japanese wood saws) or have a very comfortable anatomical handle that protects the hand.

Previously, the main material for handles was wood. Now it has lost some of its positions to metal, plastic and rubber. Which one to give preference depends on the type of work planned, its duration, and the available budget.

Lesson “My profession is a construction carpenter”

professional educational institution

Lesson game: “My profession is a construction carpenter”

Developed and conducted by a master of industrial training: Lyudmila Ivanovna Andreeva

The lesson is designed for students where graduates of special (correctional) schools of the VIII type study, within the framework of the week

by profession: 18880 “Construction carpenter”

duration of study: 1 year 10 months.

1. Students must understand the essence and social significance of their future profession, show sustained interest in it, and realize their capabilities.

2. Consolidate the acquired knowledge in the subjects - “Technology, materials science, labor protection. »

4.Work in groups. Develop collaboration skills; communication skills.

Educational: To form motivation and interest in work activities. Consolidate acquired knowledge in the disciplines “Occupational Safety” and “Technology”. "Materials Science".

Correctively. developmental: Develop accuracy of perception of verbal material, intensify mental and creative activity.

Educational: Develop students’ skills in joint activities; communication skills; help realize the abilities and interests of students in the chosen activity. Form goodwill and perseverance.

The formation of value orientations, beliefs, and an active life position contributes to the involvement of students in the active process of obtaining and processing knowledge. In my opinion, these requirements are implemented in the proposed development

The lesson can be held in a classroom.

Design: The topic, purpose and objectives of the lesson are written on the board.

1. Determining the topic of the lesson; choosing the purpose, content, form; involving as many participants as possible in the process of preparing and conducting

2. Determination of the date and location of the lesson; drawing up a plan for preparing and conducting a lesson.

4. Conducting a lesson; analysis and evaluation of the effectiveness of the lesson and activities for its preparation and delivery.

The teacher greets students:

Hello. guys, dear guests! Today we have an unusual activity: a game lesson. I hope that you will be active, diligent, and smart. Today we will talk about work, about the profession of “Construction carpenter.” Before we start the game, let's get acquainted with the lesson plan and the rules of the game.

- “Own game”. testing of knowledge in the disciplines - “Occupational Safety”, “Technology”. "Materials Science".

- Riddles competition - knowledge of the tools used in the profession: “Construction carpenter.”

- Proverb competition about work.

Grading criteria: Each correct answer is worth one point.

Sources:

https://enkistroy.ru/raznoe/vidy-ruchnyx-pil-vidy-pil-ix-naznachenie-i-xarakteristiki-kakie-byvayut-pily.html https://greensector.ru/instrumenty-i-tekhnika/kakie -byvayut-pily-osnovnye-vidy-i-kharakteristiki-istrumenta.html https://mega-talant.com/biblioteka/urok-moya-professiya-stolyar-stroitelnyy-88071.html